Photo credit: Lockheed Martin

GE Aerospace and Lockheed Martin completed a series of engine tests demonstrating the viability of a liquid-fueled rotating detonation ramjet for use in hypersonic missiles, the first initiative between the companies under a broader joint technology development arrangement.

The companies conducted direct connect tests in ramjet ignition and cruise conditions at the GE Aerospace Research Center in Niskayuna, New York, to demonstrate the operation of an air-breathing rotating detonation ramjet for missile applications. Engineers injected air into the inlet to represent supersonic flight at various speeds and altitudes, including high cruising altitudes where the thin air challenges robust combustion.

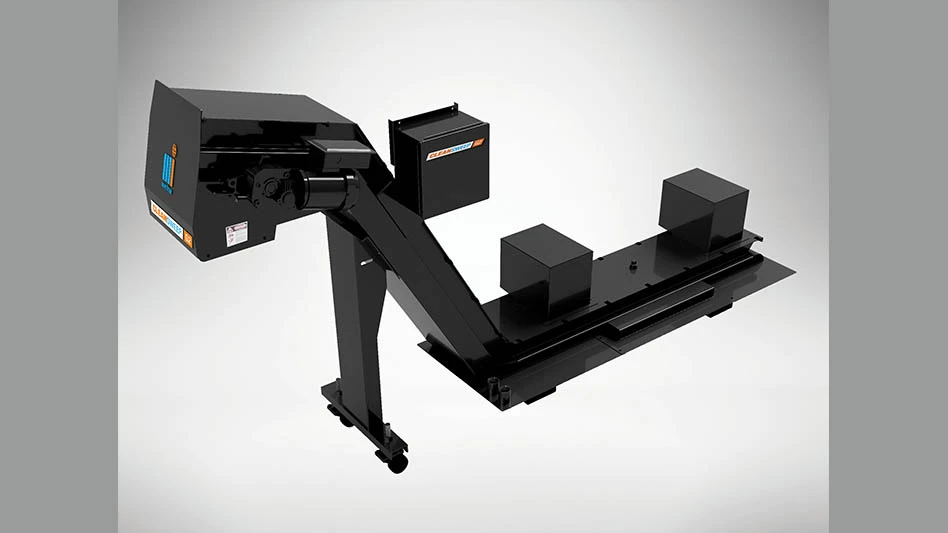

The ramjet features GE Aerospace’s rotating detonation combustion system and Lockheed Martin’s tactical inlet that enables high-speed airflow to the combustor.

This fuel-efficient rotating detonation ramjet promises to fly missiles faster – including at hypersonic speeds – and farther while decreasing costs compared to other ramjet options. Here’s how:

• The compact design enables increased fuel or payload capacity and lowers the cost of production

• Improved fuel efficiency and thrust generation extends range

• Ignition is achieved at a lower speed, so smaller boosters can be used for ramjet start

The rotating detonation ramjet combusts fuel and air through detonation waves instead of the traditional combustion methods used in ramjet engines today. This propulsion system generates high thrust for super- and hypersonic speeds to engage high-value, time-sensitive targets, with a smaller engine size and weight that boosts range.

“GE Aerospace’s hypersonic capabilities continue to advance at a rapid pace, and this collaboration with Lockheed Martin is another step forward in our journey,” said Mark Rettig, vice president and general manager of Edison Works Advanced Programs at GE Aerospace. “The testing on the rotating detonation ramjet and inlet exceeded expectations, and we are excited about this collaboration to continue maturing our advanced air-breathing hypersonic propulsion technologies.”

GE Aerospace’s Edison Works is an advanced design, engineering, and technology organization within the company dedicated to developing the next generation of defense propulsion and systems. With a focus on rapid prototyping, digital engineering, and groundbreaking innovation, Edison Works is where GE Aerospace pushes the boundaries of what’s possible to define the future of flight.

"Following two years of internal investment, this demonstration is a testament to the power of collaboration, innovation and joint commitment to get affordable capability into the hands of warfighters at the speed of relevance,” said Randy Crites, vice president and general manager at Lockheed Martin Advanced Programs. “This compact ramjet applies Lockheed Martin’s expertise in ramjet inlets and offers extended range at extreme speeds. We’re committed to delivering a propulsion system that advances America’s hypersonic capability in an intensifying threat environment.”

GE Aerospace and Lockheed Martin will continue ramjet maturation in 2026.

Latest from Aerospace Manufacturing and Design

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators

- How should you approach automation?

- Take a break and learn something new about manufacturing over lunch

- DMG MORI plans $40.5 million expansion in Illinois

- Compact, azimuth-elevation two-axis gimbal mount

- Workholding Roundtable Webinar

- RTX's Pratt & Whitney broadens manufacturing capabilities in Columbus, Georgia