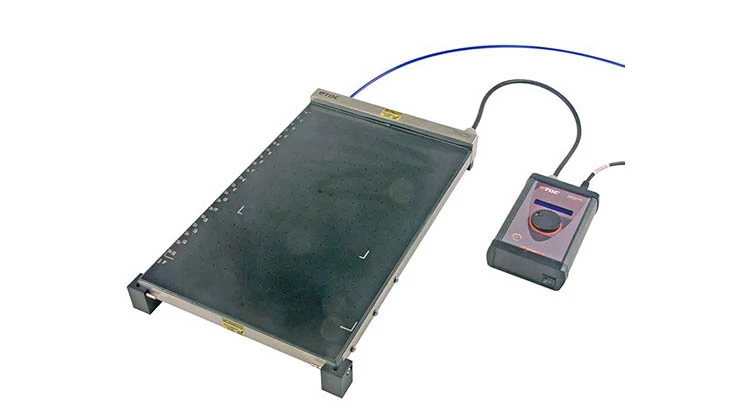

Pompano Beach, Florida – The new heated, perforated vacuum bed table can be used to create smooth and consistent thin films of paint, lacquers, and other materials on sample specimen such as opacity test charts, sample panels, foils, or other flat substrates.

The vacuum table is made of hard aluminum and anodized in hardcoat flat black to provide a durable and inert surface with an absolute flatness. The surface of the vacuum table is perforated with a grid of small holes which hold the test specimen in position for proper drawdown when attached to a vacuum pump or line (not included).

The vacuum table has a built-in heating mat which allows the temperature of the table to be elevated up to 100°C above ambient temperature. The powerful heating device guarantees an even distribution of the temperature over the entire vacuum plate. Temperature is set and controlled through a digital temperature controller.

Unlike with the automatic film applicator, the films are to be applied manually using a variety of applicators such as block-applicators, Baker-applicators, bar-coaters and wire wound rods, bird-applicator, quadruple applicators, Biddle duplex applicators, System Wasag, casting knife, and micrometric film applicators.

Features

- Durable and inert surface with an absolute flatness to be used with charts, foils, panels, and other flat surfaces

- Even temperature distribution

- Digital temperature control

- Vacuum keeps the test specimen in position

- Item Nos. #DP-320105, #DP-320115

Paul N. Gardner Co. Inc.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools