Saginaw, Michigan – Fullerton Tool Co. is now an authorized manufacturer and distributor of 5ME’s BlueZone Cryogenic tooling, after the two companies finalized an agreement that includes sales and support for carbide end mills and drills designed for use with 5ME’s cryogenic machining systems. The agreement covers sales and service in the United States, Mexico and Canada.

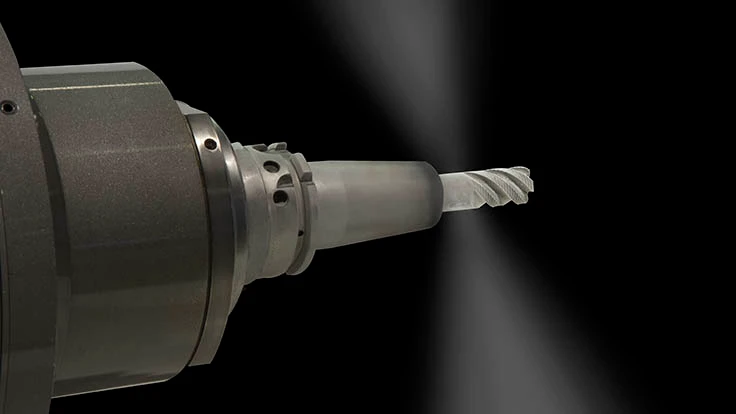

5ME’s multi-patented cryogenic machining process enables higher cutting speeds, increased material removal rates, and longer tool life by transmitting liquid nitrogen at 321°F through the spindle/turret and tool body, directly to the cutting tool’s edge.

“Fullerton’s reputation for providing top-quality carbide tooling, as well as outstanding service and support made it a natural choice as a tooling partner,” said Bill Horwarth, president of 5ME. “We’ll work closely with the Fullerton team to develop the next advanced-performance BlueZone tooling, as well as testing on materials to optimize coatings, cutting geometries, and machining parameters.”

Fullerton is a family-owned, U.S.-based company that provides custom carbide cutting tools for demanding applications.

“The Fullerton Advanced Solutions Team (FAST) specializes in improving tool performance and reducing lead times – a perfect complement to 5ME’s cryogenic machining technology,” said Patrick Curry, president of Fullerton Tool Co. A fully equipped research and development lab enables FAST engineers to design and manufacture special cutting tools and prove out machining methods that lead to lean, efficient and profitable processing.

Applications for cryogenic machining include high-speed cutting of titanium and other tough-to-cut alloys common in aerospace, heavy equipment, and energy part processing.

Source: Fullerton Tool Co.

No more results found. 5ME’s multi-patented cryogenic machining process enables higher cutting speeds, increased material removal rates, and longer tool life by transmitting liquid nitrogen at 321°F through the spindle/turret and tool body, directly to the cutting tool’s edge.

“Fullerton’s reputation for providing top-quality carbide tooling, as well as outstanding service and support made it a natural choice as a tooling partner,” said Bill Horwarth, president of 5ME. “We’ll work closely with the Fullerton team to develop the next advanced-performance BlueZone tooling, as well as testing on materials to optimize coatings, cutting geometries, and machining parameters.”

Fullerton is a family-owned, U.S.-based company that provides custom carbide cutting tools for demanding applications.

“The Fullerton Advanced Solutions Team (FAST) specializes in improving tool performance and reducing lead times – a perfect complement to 5ME’s cryogenic machining technology,” said Patrick Curry, president of Fullerton Tool Co. A fully equipped research and development lab enables FAST engineers to design and manufacture special cutting tools and prove out machining methods that lead to lean, efficient and profitable processing.

Applications for cryogenic machining include high-speed cutting of titanium and other tough-to-cut alloys common in aerospace, heavy equipment, and energy part processing.

Source: Fullerton Tool Co.