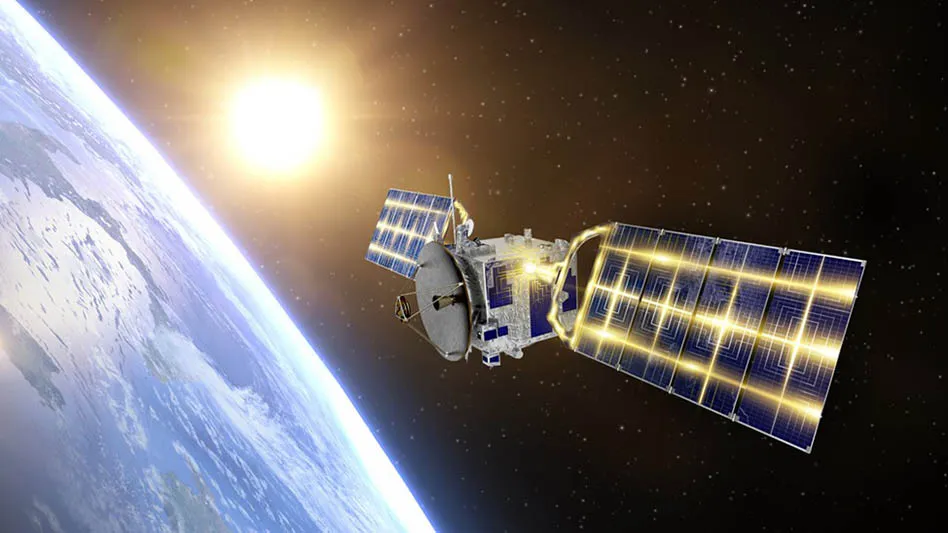

Photo credits: Texas Instruments

In an increasingly competitive aerospace and defense landscape, the demand for high-reliability (HiRel) semiconductors has never been higher. Sourcing microelectronics that can withstand the rigors of space exploration or harsh terrestrial conditions is vital for mission-critical deadlines. When failure is not an option, companies need access to available inventory and a streamlined purchasing process to secure products quickly and at scale.

Let’s take a look at some of the most important considerations for companies looking to source and purchase HiRel integrated circuits.

Convenience

Compliance with industry standards and regulations is non-negotiable in space and defense applications, with components requiring sophisticated documentation detailing conformance to quality specifications and test data.

Companies working on government-based missions must submit paperwork to authorities to demonstrate compliance. Procurement teams should work with certified suppliers that provide processing conformance reports (PCRs) and quality conformance inspection reports to ensure product quality and reliability, from design to fabrication. The ability to seamlessly obtain this documentation is vital when matching HiRel needs with supply.

Transparency is also important when purchasing semiconductor products, but it’s not always offered through online sales channels. Texas Instruments (TI) is the only manufacturer in the industry that allows customers to download all of the product and ordering online documentation they need to purchase HiRel analog and embedded processing products. This includes PCRs for individual manufacturing lots and characterization data for new product releases TI’s website also offers customers the functionality to search for HiRel products by date codes.

“The ability to track date codes is important because manufacturing variance occurs most across different lots. When customers acquire a group of parts from a single lot, they feel more confident that the parts will all perform at a consistent level,” said Mark Toth, TI’s Space Power marketing and applications engineering manager.

Clear lead times and pricing

Competition is driving HiRel suppliers to minimize lead times for product orders, but components can still require up to 52 weeks to provision given the complexity of manufacturing and testing. Fluctuating inventory levels can be challenging when needing to secure sufficient stock by mandated deadlines. Uncertainty about inventory and pricing only adds to the frustrations. Purchase managers should opt for suppliers who are transparent about lead times and upfront about cost.

“TI has built transparency into TI.com, giving customers more visibility into lead times through an API. Our website also includes a feature called ‘future inventory,’ which gives notice of future replenishments for HiRel products, including timelines and quantities,” said Laura Shuey, TI's e-commerce marketing manager. “It’s a clear part of our strategy to enable customers to purchase as seamlessly as possible, whether for immediately available inventory on TI.com or longer-dated orders.”

HiRel demands change as companies evolve and priorities shift

The aerospace and avionics industry is changing rapidly, with new players joining traditional manufacturers in a dynamic market. Startup companies are launching small satellites, while other firms are making their first forays into space after developing land-based industrial systems. Meanwhile, manufacturers with a record of success building sophisticated systems for deep space exploration are looking to produce more nimble solutions on a smaller scale.

“The trend is in both directions – small companies are looking to move up the scale, and large ones are hoping to move down into more cost-effective systems,” Toth said.

While priorities vary, procurers should focus on suppliers with the scale and knowhow to work with them as their companies’ HiRel demands evolve. For example, TI has a line of Space EP products intended for shorter, low Earth orbit satellite missions, while continuing to offer traditional Qualified Manufacturers List-certified products for the longest space missions.

“We’ve been creating HiRel devices since the 1950s. So we have a good portfolio of legacy products and at the same time take pride in new product development,” Toth said.

While developing HiRel products with the durability for deep space, TI is making it easier for customers to secure them on land. Providing on-demand documentation and transparency in pricing and inventory, TI understands that a smooth purchasing process can be a launch pad for success.

Texas Instruments

TI.com/space

Latest from Aerospace Manufacturing and Design

- Latest advancements in machine tool technology

- Visit Okuma America at IMTS 2024

- AM for Aircraft Cockpit Interior Components

- Piasecki Aircraft reveals hydrogen-powered UAM progress

- Siemens' Simatic Workstation

- Heart Aerospace to open US R&D hub

- Comau's S-Family of small industrial robots

- GrindingHub: a showcase for international grinding technology