PHOTO CREDIT: SIEMENS INDUSTRY INC.

Once the realm of science fiction, the idea of a flying car has come to life in electric vertical takeoff and landing (eVTOL) aircraft, also known as air taxis. Akin to a helicopter, these aircraft use multiple battery-powered rotors to hover, take-off, and land vertically. In fact, their aeronautical operating principles are not unlike those of commercial and hobby drones.

Typically, eVTOL aircraft have short-hop ranges of under 100 miles and cruising speeds between 100 to 200 miles per hour. They are designed to safely conduct military and civilian applications ranging from passenger transport to medical evacuation operations.

So far, piloted prototypes of many leading manufacturers have gained approvals by the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). Of course, Airbus and Boeing are heavily invested in this technology, as are major airlines and car makers. Unit eVTOL sales are forecast to grow 25%, compounded annually through 2044. [Air Taxis: Electric Vertical Take-Off and Landing (eVTOL) Aircraft 2024-2044: Technologies, Players. IDTechEx. March 2024.]

Because the safety of eVTOL aircraft requires extremely reliable performance of its electric motors, testing them under simulated flight loads and beyond are critical. The industry’s need for precise, efficient, and cost-effective dynamometer testing systems has been an opportunity for ACS, a CE- and UL 508 A-certified Siemens solution partner.

As a leading systems integrator and provider of advanced testing solutions for electric powertrains based in Verona, Wisconsin, ACS also serves markets including consumer, automotive and commercial vehicles, aerospace and defense, energy, industrial, manufacturing, agriculture, mining, and laboratory facilities. It can build systems that qualify for NEMA Type 1, 12, 3R, 4, 4X designations as well as NEC Class I Division I explosion-proof operation.

Challenge: Design, engineer, and build a four-axis dynamometer testing system for high-resolution, flight-load simulations on an extremely tight schedule

According to ACS Director of Facility Planning and Integration Matt Thiel, the company was approached by one of the eVTOL industry’s most promising aircraft manufacturers to design, engineer, and build a four-axis dynamometer testing system. The customer also needed it ready for commissioning and deployment in just a few months’ time to meet a tight market introduction schedule and the rigorous expectations of investors.

Thiel says: “Because their prototype aircraft’s rotors will be powered by four large, battery-operated electric motors, they need to test each motor’s output to ensure it delivers the correct speed and torque. They also must test each motor’s endurance and response time, in addition to a long list of other variables.

“So, to do that, they’ll connect our system to each motor to be used on one of their aircraft to simulate a rotor’s aerodynamic loading and ensure they perform as expected, including the operation of their safety control functions. The dynamometer system is designed to match the speed and the load as calculated or measured in actual take-offs, landings, and flight paths.”

Testing via an ‘iron bird’

Thiel explains that the ACS dynamometer is part of the eVTOL maker's component development, testing, and systems integration laboratory. He notes that ACS has designed and constructed numerous similar integrated facilities, including many with chambers capable of simulating climate and altitude conditions. However, for this customer, the focus was on the dynamometer system, its installation, and its commissioning.

“For testing their propulsion systems using our dynamometer, their engineers will assemble the complete propulsion, power, and control system for their aircraft, as it would be in an operating eVTOL, with the motors, their controllers, the correct wire lengths and all other critical components,” Thiel says. “In the aerospace industry they call this setup an ‘iron bird,’ and it is used to validate the vehicle with all the hardware and controls in the loop.”

Solution: Use Siemens high-performance drive and induction motor technologies to reduce development cycle times, including integration and testing

Many ACS customer engagements involve building not only the test equipment, such as the advanced dynamometer system built for the eVTOL aircraft manufacturer, but also the entire integrated test facility. In the decades since the company’s founding in 1994, ACS has developed its trademarked Ntandem solution development methodology.

“As the Ntandem name implies, it is a collaborative process we’ve developed over the years to handle complex capital projects needing integrated test and process solutions,” Thiel says. “We work closely with each customer’s engineering and operations teams using Ntandem as a proven process, which also incorporates disciplined project management, to consistently deliver validated technical assets that work as intended, on schedule, and on budget.”

Proven methodology to de-risk projects

The Ntandem approach is flexible to accommodate a wide range of project execution models, from having ACS deliver an entire turnkey project to working with customers who may have hired an architect, engineering firm, or general contractor or have the capability to take a DIY approach to certain aspects of the required project scope. Because the eVTOL aircraft maker had a third party building its lab, it relied on ACS to focus on delivering their dynamometer test system.

But the proven Ntandem methodology helped to de-risk the project. “The timeframe was so tight, there was no room in the schedule for miscommunications, misunderstandings, or mistakes,” Thiel says.

“That’s why we planned for more than simply shipping the dynamometer test system, and in partnership with the customer, we first consulted with the facility builder and electrical contractor to ensure all the electrical and foundation requirements for our system’s installation, commissioning, and start-up were in the plans and ready upon its arrival.”

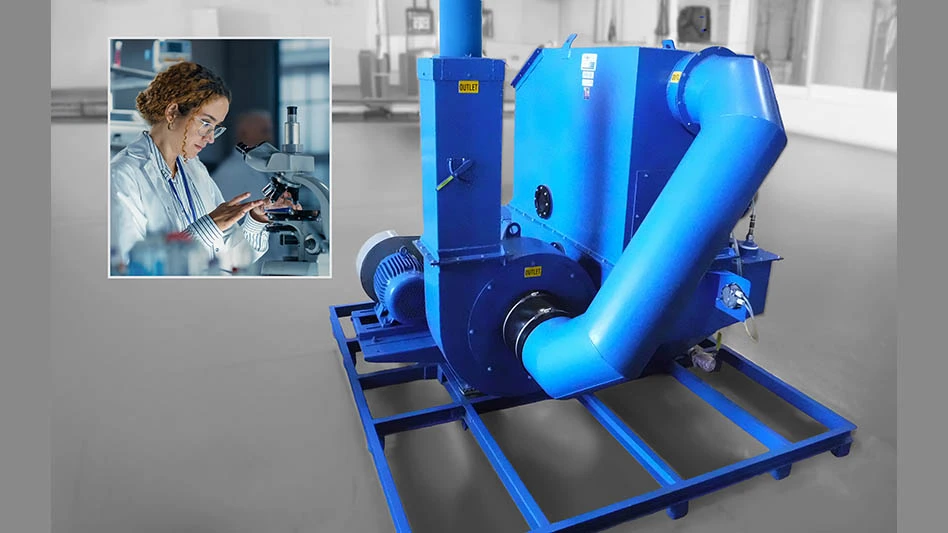

4-axis, 1,205hp (900kW) AC regenerative drive system

To simulate flight loads on the eVTOL’s four electric motors, ACS built a 4-axis, 1,205hp (900kW) AC regenerative drive system with 480V, 1,200A, 3-phase power. The drive system powered four 335hp (250kW) motors, each one coupled to a propeller drive motor destined for use in the customer’s eVTOL aircraft. Each dynamometer motor rests on a riser that contains all the connections necessary to run the system and precisely test the corresponding drive motor’s performance characteristics. The customer provided the aircraft controller and data acquisition system for the testing, and ACS integrated its dynamometer controller functionality within their software platform to allow for seamless operation.

The regenerative design enables the energy captured from each dynamometer motor absorbing load to be used to operate the motors in the system that may be outputting power during the test or to be fed back to the facility grid, offsetting other power consumption in the building.

This approach offers two benefits. First, it can diminish the size and cost of power electronics needed for connecting to the grid or decrease the energy storage capacity of a battery power source. Second, it eliminates the need for a load-bank system to dissipate the energy produced by the dynamometer as waste heat.

To further de-risk the project’s strict timeline, ACS used Siemens SINAMICS S120 drives and asynchronous SIMOTICS M-1PH8 induction motors. As a Siemens solution partner, the company’s engineers were familiar with these product families. “This Siemens drive system is high-performance and extremely versatile, enabling the precise control of our customers’ subject electric motors,” says Thiel, noting that a Siemens SIMATIC S7-1500 PLC provides a communication gateway between the SINAMICS drives and the host controller for robust dynamometer operation.

He adds: “Also, the out-of-the-box, plug-and-play integration of Siemens drives and motors ensured their interoperability, so our engineers could focus their time on critical system design tasks rather than getting the components to work together. Plus, the Siemens components’ adherence to standardized industrial communications protocols made connecting them with the customer-provided SCADA system a straightforward task.”

Results: Met customer commitment, enabling eVTOL prototype flight-load testing and gaining a valuable test system reference in a fast-emerging market

Thiel reports that the ACS dynamometer test system was considered a critical-path item on the eVTOL manufacturer’s product testing and certification timeline. “In making our delivery commitment on time as promised, we relieved our customer of any concerns about having our test system on hand when the program needed it,” he says. “Also, our advance consultations with both the general and electrical contractors provided even more assurances that our equipment would be properly installed, commissioned, and operating in short order.”

Additionally, the ACS team was able to assure the customer that the Siemens drive system, integral to the ACS dynamometer solution, would deliver the testing precision required to meet the rigorous flight certification standards of the FAA and EASA.

“One of the key criteria in our test systems is that their measurement and control resolution has to be as much as five times more precise than what the tested unit can do, which the Siemens drive system helps us achieve,” Thiel says. “This enables our customers to detect and resolve whatever differences they might find in their motor’s tested operating performance relative to its design specifications, whether that’s mechanical, electrical, or in its controls.”

With the successful completion and delivery of its dynamometer test system for an eVTOL industry leader, ACS now has a valuable reference in a fast-emerging market. “While testing the electrical propulsion systems of eVTOL aircraft is certainly an exciting opportunity for us, we now have a reference architecture to help us capitalize on the even bigger trend in the electrification of just about everything, a market push which will help decarbonize the world and make industry and transportation much more sustainable,” Thiel says.

With an eye to the future, ACS considers Siemens a strategic partner that is always ready to provide engineering and product support at its headquarters as well as wherever in the world its testing systems may be deployed. “We’re always looking to expand our horizons, in terms of technologies, capabilities, and markets,” he says. “Our relationship with Siemens is more than transactional. We are a solution partner and can count on them to continue pushing the boundaries of what’s possible, which will help keep us at the forefront in our field for many years to come.”

Siemens Industry Inc.

Digital Industries – Motion Control

https://www.siemens.com/us/en/company/about/businesses/digital-industries.html

About the author: John Meyer is marketing communications manager for Siemens Industry Inc., Digital Industries – Motion Control.

Latest from Aerospace Manufacturing and Design

- The latest workholding technology to boost productivity and efficiency

- There’s still time to register for our 2026 Manufacturing Forecast roundtable!

- Vertical Aerospace brings Valo to New York

- Industrial display for enhanced HMI, visualization

- Eve Air Mobility secures $150 million financing

- Tooling optimized for aluminum, titanium, and nickel alloys

- Additive Manufacturing: Analysis. Trends. Forecasts. webinar with Terry Wohlers

- Ethiopian Airlines orders nine Boeing 787 Dreamliners