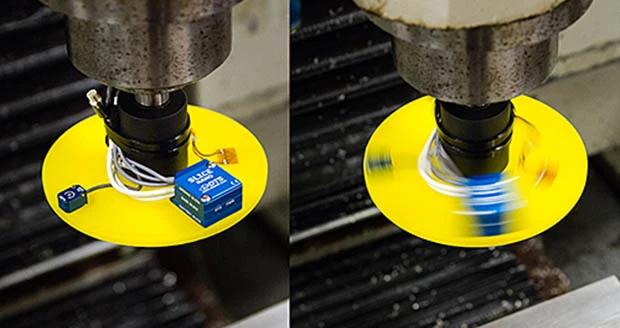

A 3-channel DTS SLICE data recorder, including battery, is mounted directly on a CNC shaft along with strain gauges to measure torque and a DTS ARS PRO angular rate sensor to measure angular velocity.

Seal Beach, California – For anyone challenged with collecting data on rotating components such as drive shafts, rotors, reciprocating rods, or even track vehicle treads – there is now a solution from California-based DTS that eliminates the need for slip rings and telemetry.

The miniature SLICE data recorder is so small it can be easily mounted directly on the test article – so no slip rings and no telemetry are required. SLICE fits on virtually any moving or rotating part without altering test dynamics, yet it's rugged enough for extreme test environments. For applications such as measuring torque on a drive shaft, SLICE mounts directly on the shaft next to the strain gauges, ensuring high data quality while eliminating issues with noise, data transfer, and cumbersome fixtures.

Unlike other data acquisition systems (DAS) that are typically much larger, SLICE includes everything needed to record sensor data autonomously. The built-in microprocessor manages a full-featured signal conditioning and storage system that includes independent excitation sources, variable gain amplifiers, adjustable sampling rates from 10sps to 500ksps, and adjustable anti-alias filters up to 40kHz. One of SLICE's key features is the 16GB direct-write flash memory that can record high sample rate data continuously for hours, unlike older systems with memory limited to a few seconds or minutes. Plus, embedding SLICE in the test article reduces cabling concerns and makes installation easier.

Each 3-channel slice or layer is modular and weighs less than 14g, making mounting and balancing the system without altering test dynamics simple. SLICE supports bridge sensors, strain gauges, IEPE sensors, voltage inputs, and temperature sensors. Because SLICE stores all data onboard, it eliminates reliability issues from streaming data, especially with higher channel counts or high bandwidth tests. Designed for field testing, SLICE is shock rated up to 5,000g making it suitable for a variety of rotating applications in automotive, aerospace, and military.

Founded in 1990 by three crash test engineers, DTS data recorders and sensors are used worldwide in crash, blast, and biomechanics testing by automakers, aerospace, and research facilities. Based in Seal Beach, California, DTS has technical centers in Michigan, Australia, China, the U.K., and Japan.

Source: DTS

Latest from Aerospace Manufacturing and Design

- The Lee Company opens Innovation Center

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family