Doncaster's Groton

Doncasters has successfully commissioned a brand-new, fully automated shell line at its Groton, Connecticut facility – a major milestone within its 2025 Performance Improvement Plan and a key advancement in the company’s long-term manufacturing strategy.

The $13 million capital investment expands the Groton site’s operational footprint by 17,000 square feet and introduces next-generation automation and environmental control systems.

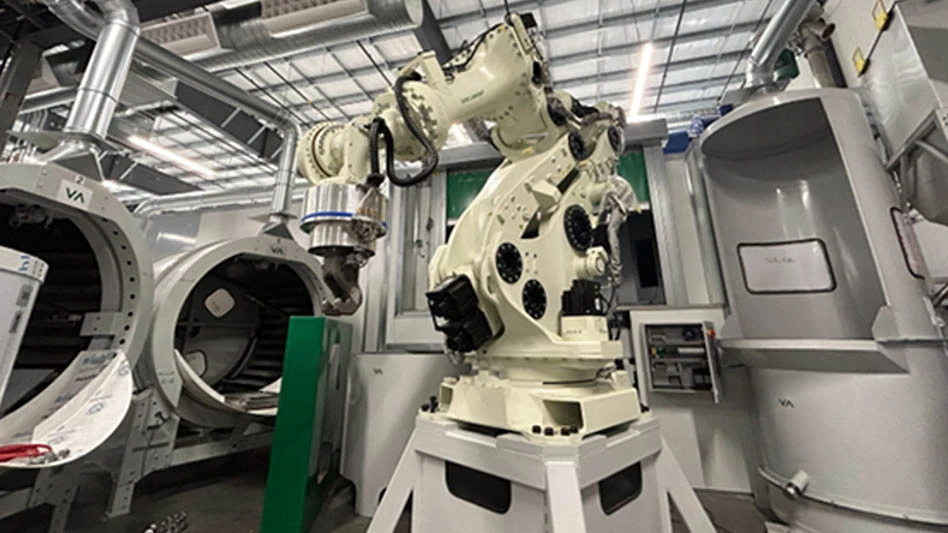

Equipped with three high-precision 6-axis robots and the industry-leading IC-Crystal Shell Management System, the new line significantly enhances production capacity, part quality, and operational reliability.

“Our new fully automated shell system isn’t just a machinery upgrade – it’s a strategic leap forward,” said Mike Looney, GM at Doncasters Groton.

“This investment dramatically enhances our efficiency, precision, and capacity, enabling us to take on more complex, high-volume aerospace products. It positions us to meet rising industry demand and deliver unmatched quality to our customers around the globe.”

The former shell system – installed in the 1980s – suffered from limited capacity, minimal process control, and frequent downtime due to heavy reliance on manual operations. The new system addresses these challenges with the following benefits:

- Quadruples output capacity – from 10 molds per day to 40 hangers per day

- Minimizes process downtime through full automation and telemetry-enabled quality tracking

- Improves mold quality with precise sanding and dipping performed by 6-axis robotic arms

- Reduces operating costs via advanced environmental controls and efficient processing

- Accelerates turnaround times through stable, rapid drying and optimized shell handling

Key system features

- 6-axis robotics: Greater motion control reduces mold damage and ensures a superior surface finish

- IC-Crystal Shell Management: Tracks all critical-to-quality parameters – slurry conditions, equipment status, and environmental controls

- Environmental precision: Maintains strict temperature (±2°F) and humidity (below 20%) to prevent shell defects such as splits or cracks

- Engineered core packs: Eliminate manual handling, freeing up operators to focus on skilled tasks

- Low-maintenance upgrades: New systems replace high-impact equipment like fluidized beds and vertical sanders with more sustainable alternatives.

To date, 48 molds across six part families have been successfully substantiated in the new system.

The first phase of legacy system decommissioning is nearly complete, with final demolition expected by October 2025.

Latest from Aerospace Manufacturing and Design

- GE Aerospace demonstrates narrowbody hybrid electric engine

- 1, 2, and 3-axis standalone motion control systems

- TMTS 2026 explores AI-powered sustainable manufacturing and more

- Expanded line of blind-hole and through-hole taps

- EMCO Corp. opens state-of-the-art showroom

- Expanded two-axis laser scan head line

- The latest workholding technology to boost productivity and efficiency

- There’s still time to register for our 2026 Manufacturing Forecast roundtable!