All photos courtesy Brush Research Manufacturing Co. Inc.

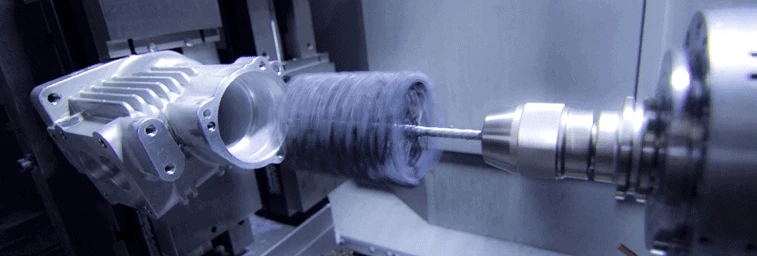

Removing burrs and sharp edges in cross-drilled holes and other difficult-to-access machined areas such as undercuts, grooves, slots, or internal holes can be tedious and time consuming. A particular challenge: deburring the intersection of cross-drilled holes in jet engine components.

Despite challenges, removing burrs is a must for high-quality, precision parts. Cross-drilled holes act as conduits for fluids, lubricants, and gases, so failing to remove burrs can block critical passages or create turbulence in the flow. Burrs can also lead to part misalignments, affect dimensional tolerances, and limit overall component efficiency.

Huntington Beach, California-based Delta Machine Co. LLC, a machine shop specializing in complex, tight-tolerance aerospace parts made of titanium, nickel, exotic alloys, stainless steel, aluminum, and plastics, pays close attention to deburring tools.

Read the full article now!

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools