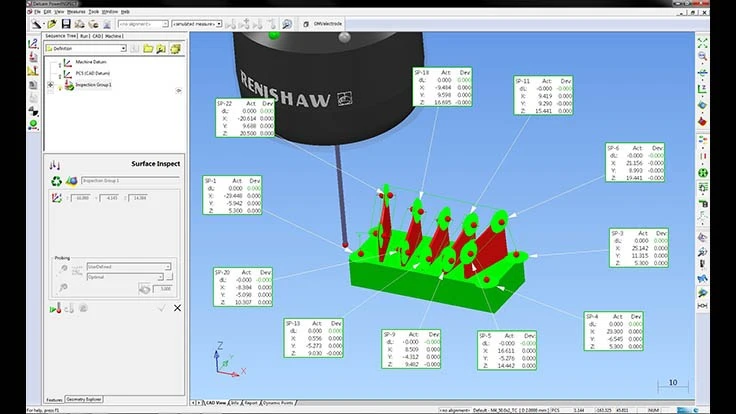

Data collected with PowerINSPECT offer many ways to improve productivity.

Birmingham, United Kingdom – Delcam will hold two webinars on Nov. 24, 2015, at 4am EST and again at 11am EST, explaining how metrology can contribute to increased productivity and profitability at manufacturing companies. The webinars will explain how measurement data collected with Delcam’s Advanced Manufacturing software can allow users to reduce cycle times and minimize rejection rates.

For full details and to register for the webinars, please visit the PowerINSPECT website.

The webinars will demonstrate five areas where measurement can help – final inspection, optimized manufacturing, shorter set-up times, automation, and repeatability.

Final inspection ensures that non-conforming parts never reach the customer, an important consideration as parts become more complex and tolerances get tighter. The other big benefit from using PowerINSPECT is the ability to produce professional reports, customized to present the results exactly as the customer requires, with data and easy-to-understand diagrams to confirm that the parts have been machined to the specified tolerance.

Inspection is not only needed at the end of any process. Regular inspection during manufacture optimizes processes by allowing errors to be corrected more quickly. It can even enable any drift in the results to highlight a potential problem before out-of-tolerance parts are produced. Scrap-or-save decisions can be made earlier, preventing further work on parts that are already too far away from specification.

Finish machining of near-net-shape parts, such as castings and forgings, can involve long set-up times. PowerINSPECT can minimize these delays by establishing the positional relationship between the part and the machine, and then adapting the machine’s coordinate system to the part’s exact location. This faster and more consistent set-up gives improved machine utilization and reduced need for operator intervention.

Measurement can be used to overcome variation in finishing processes such as polishing, linishing, deburring, and trimming that have previously needed manual processes. The resulting automated solutions allow robots or automated work cells to be used to improve consistency and reduce costs.

As well as ensuring consistent process quality, measurements can improve repeatability when they are used to identify and compensate immediately for minor variations resulting from wear in the machine or cutting tool and to predict maintenance requirements in the longer term.

Source: Delcam Ltd.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators