Photo credit: ©Daher

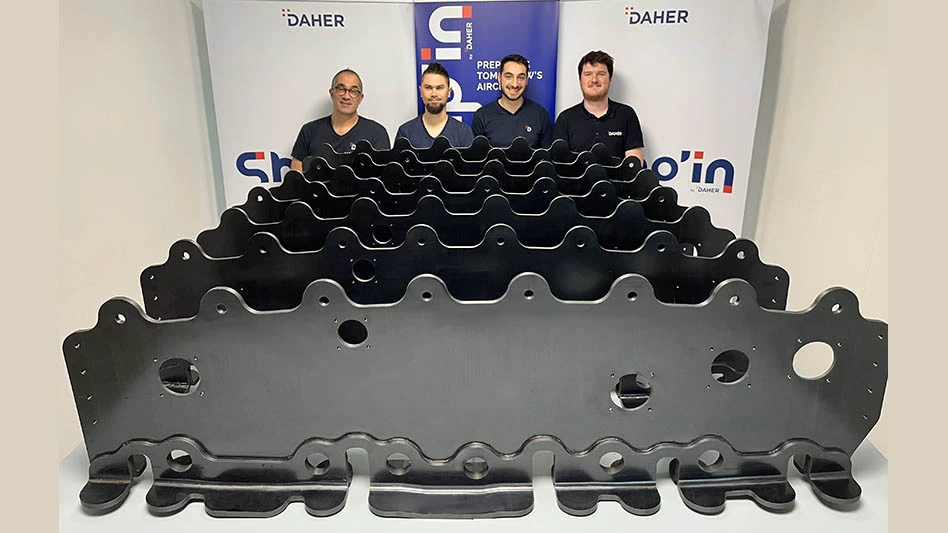

Daher received the JEC Composites Innovation Award in the Aerospace Parts category for its “Highly Loaded Thermoplastic Wing Rib,” which was developed for future aircraft programs.

The award recognizes the work of Daher and its partners – Victrex, Luxembourg Institute of Science and Technology (LIST), CETIM, and AniForm – in developing an innovative solution that addresses major challenges in decarbonization, cost reduction, and high-rate production for next-generation commercial aircraft.

The Innovation Award from the JEC Group – a non-profit organization dedicated to promoting composite materials and fostering their applications globally – was announced during the JEC World Premiere event in Paris, France.

A wing rib is a key structural component of an aircraft wing: it maintains the aerodynamic profile, ensures rigidity, and distributes loads between the wing skin and the spars.

Building on the Wing of Tomorrow program established by Airbus, Daher focused its work on wing ribs for the optimization of cost, weight, and carbon footprint. The award-winning rib is made of CFRTP (carbon fiber reinforced thermoplastic) composite and features a significant thickness – up to 64 plies (12mm) – to meet the performance and production rate requirements of aircraft manufacturers.

The wing rib’s development project incorporated several major innovations:

- Optimized design: Integration of optimized ply drops, reduced joining surfaces, and a proven stiffener less geometry to improve the mass to cost ratio

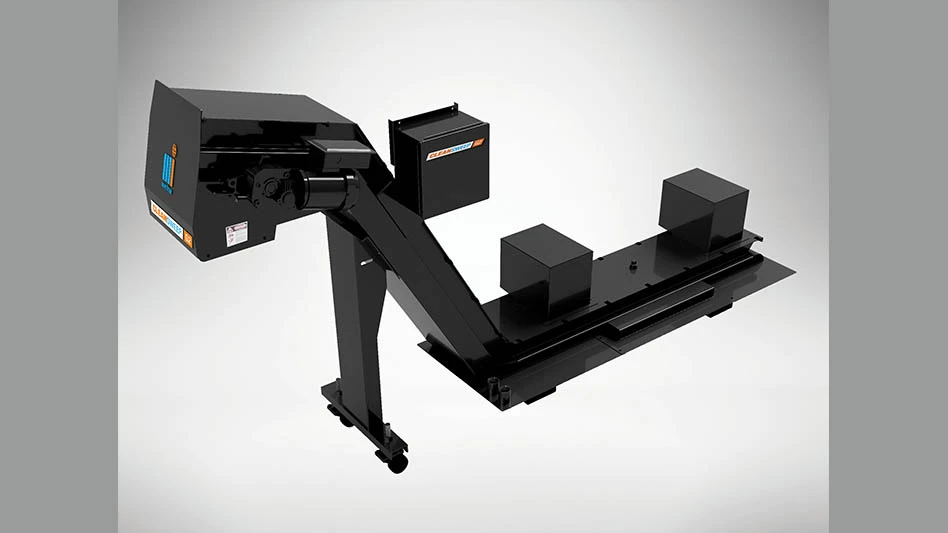

- Direct Stamping (Daher patented technologies): Elimination of a consolidation step between lay-up and stamping, reducing cycle time and manufacturing cost

- Infrared welding (LIST patented process): Fast assembly of the two elementary parts to form the T shaped rib; weight reduction by eliminating rivets

This innovation reduces weight (-22% compared with aluminum), lowers assembly costs (-15% compared with a bolted assembly), and shortens production cycles (-25% compared with a bolted assembly) – all while meeting the high-rate production needs for future aircraft. It also contributes to lowering fuel consumption and CO₂ emissions (-12.5t CO₂ per rib over the lifetime of a single aisle aircraft), with the added advantage of thermoplastics recyclability (unlike thermoset composites).

Launched by Daher in 2021, the Highly Loaded Thermoplastic Wing Rib project brought together key partners to develop patented processes and advanced simulation, paving the way for a new generation of aircraft structures.

“The JEC Award recognizes our commitment to advancing composite technologies for aerospace,” explained Dominique Bailly, the Research & Development Director at Daher. “At Daher, we’re convinced that by combining innovative materials with advanced processes, we can successfully deliver performance, competitiveness, and carbon footprint reduction – meeting the major challenges faced by aircraft manufacturers: high production rates, cost reduction and the decarbonization of future programs.”

Latest from Aerospace Manufacturing and Design

- DMG MORI plans $40.5 million expansion in Illinois

- Compact, azimuth-elevation two-axis gimbal mount

- Workholding Roundtable Webinar

- RTX's Pratt & Whitney broadens manufacturing capabilities in Columbus, Georgia

- Solid carbide drill range with deep hole drilling capability

- Integrion Automation announces CEO transition

- Entry-level post-processing system

- Airbus unveils next generation rotorcraft concepts