Coldwater, Ohio – Coldwater Machine Co.’s Solid State Joining Center is opening a Materials Evaluation and Testing (MET) Lab for weld inspection as an extension of its capabilities. This on-site service provides prompt verification of weld integrity, enabling Coldwater Machine to shorten the development time for laser, solid-state, and arc welding customers.

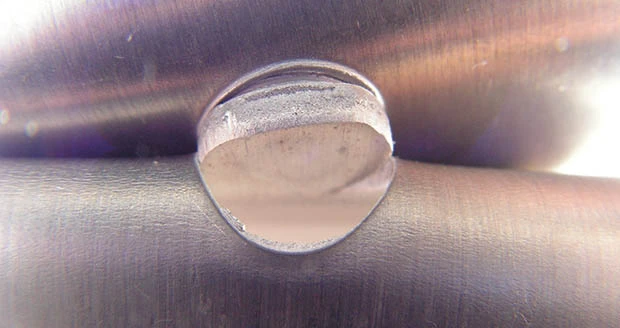

The company has invested in a new abrasive cut-off saw, metallurgical microscope with digital imaging, and a grinding/polishing station for the MET Lab in order to provide microstructural evaluation in addition to its mechanical testing capability for weld tensile and hardness.

With more than 10 years’ experience in solid-state and laser joining solutions, Coldwater Machine recently introduced two new friction welding solutions to the market. Customers interested in both solid-state prototyping and resultant lab analysis are encouraged to bring in their weld samples for evaluation by contacting the MET Lab at 419-678-4877 or emailing info@coldwatermachine.com.

Source: Coldwater Machine Co.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators