NASA's Green Propellant Infusion Mission (GPIM) has been selected to test an advanced form of thermal insulation, called integrated multi-layer insulation (IMLI), which could become standard on future satellites and cryogenic subsystems. Validating this new insulation in space will help NASA build the technology required for long human spaceflight missions. Under a subcontract from Ball Aerospace & Technologies Corp., Quest Thermal Group LLC will manufacture the new insulation that will fly aboard the 2015 GPIM mission.

High performance insulation materials are required on spacecraft and cryogenic space systems to maintain consistent spacecraft and subsystem temperatures in the space environment to keep them operating longer and more efficiently.

"Flying IMLI aboard GPIM is a win–win for the program" says Jim Oschmann, vice president and general manager for Ball's Civil Space and Technology business unit. "Conventional insulation was necessary for the GPIM spacecraft, and now we can fly a section of the IMLI at no extra cost to the program and prove it for operational use.

The new IMLI offers many benefits to conventional insulation. By utilizing rigid spacers instead of netting to separate radiation layers, it is structurally more robust, lighter, and easier to install. It also has a nearly 30% thermal performance increase over conventional multi-layer insulation, say officials. The IMLI's increased thermal capability is critical for minimizing heat transference and boil-off of cryogenic storage systems.

The IMLI manufacturer, Quest, a small company located in Arvada, Colo., is developing the technology under small business innovative research (SBIR) contracts to NASA.

"Utilizing a small business to innovate a new product and adding it to the GPIM mission demonstrates the synergy between all of the Space Technology project offices to develop and infuse technology into the market," Oschmann adds. "Our collaboration on GPIM further enables NASA to demonstrate another critical technology needed to make future space missions safer, more efficient, and more cost effective."

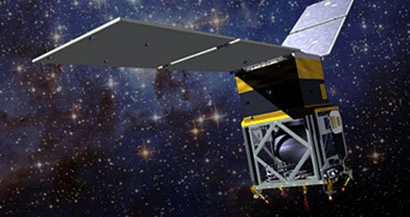

GPIM is a project for NASA's Technology Demonstration Mission (TDM) program managed by NASA's Space Technology Mission Directorate (STMD). The primary purpose of the mission is to demonstrate the viability of an alternative propulsion system for spacecraft other than hydrazine by flying a green, relatively non-toxic propellant on a U.S. Air Force-launched Ball BCP-100 spacecraft bus. Designed for easy integration of ride-share payloads, the BCP 100 spacecraft is approximately 24" wide x 28" deep x 28" high and has the capacity to accommodate up to four separate instruments.

Ball Aerospace, the prime contractor and principal investigator, leads a team of co-investigators including Aerojet Rocketdyne, Edwards Air Force Research Laboratory (AFRL), NASA Glenn Research Center (GRC), and NASA Kennedy Space Center (KSC).

Source: Ball Aerospace & Technologies Corp.