Montreal – AP&C in Montreal, Canada, a metal powder manufacturing subsidiary of additive manufacturing (AM) technology supplier Arcam AB, has added capacity by building three new atomizing reactors. The new capacity increase follows growth in 2015 and a surge in demand for AP&Cs titanium powders for AM.

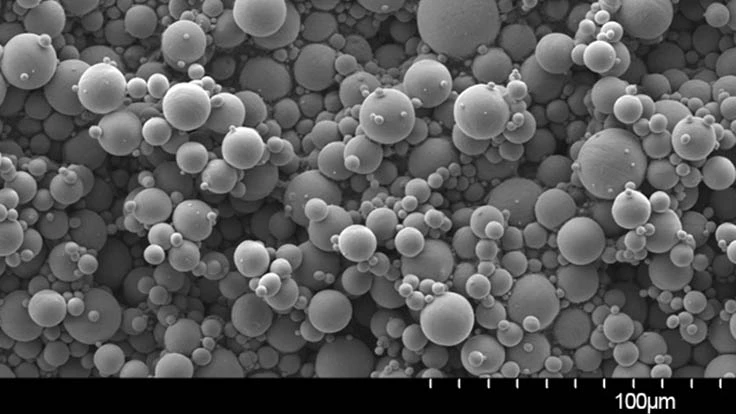

AP&C’s plasma technology efficiently converts raw material to powder with properties such as flowability, density, chemistry, and traceability. With the present build-out, AP&C will reach a capacity of at least 500 tons per year.

“Arcam is determined to serve the industry through cost-efficient solutions thus converting traditional manufacturing into additive manufacturing. A requisite is to offer highest quality powder for production at competitive cost,” says Magnus René, CEO of Arcam.

“With the new reactors and atomizing technology advancements, AP&C will triple production capacity in 2016”, says Alain Dupont, president of AP&C.

Arcam offers electron beam melting (EBM) technology for production of metal components via AM.

Source: Arcam Group

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools