Airborne

Airborne was selected by Airbus to supply an Automated Ply Placement (APP) system to the Getafe (south of Madrid, Spain) production plant, to manufacture the dry fiber preforms for resin transfer molding (RTM) structures. This will be the first time a pick & place system is used in Airbus factories, reflecting the leading position that Airborne is building for APP. The system is planned to be used for the automated production of the preforms for the A350 rear fuselage beams and maintenance door frame.

Dry fiber composites are an efficient method to manufacture complex, highly loaded primary structure. For this reason, Airbus is producing the A350 beams of the rear section of the fuselage with this technology. First the preforms are made, then shaped into the right 3D geometry by hot drape forming, and finally infused with epoxy resin by RTM.

Today the preforming is still manual, as in most aerospace factories. Automating this step has proven to be difficult. Handling of the delicate composite materials in a robust, repeatable process is challenging. Furthermore, the large variety of ply shapes and the combination of several materials into a part is complex in system design and robot programming.

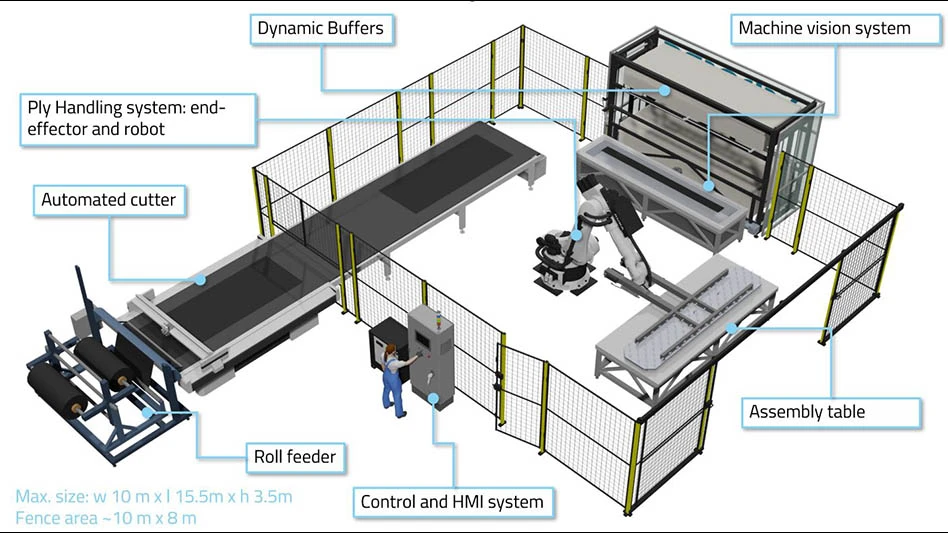

To address these challenges, Airborne developed APP technology. The concept is to cut the materials into the required shapes, pick them with a robotized system, and place them on a welding table to create the tailored blank preform. To stabilize the laminate, each ply is fixed in place by spot-welding, which activates the binder in the material. To minimise waste, the system has a dynamic buffer where the plies that are not needed yet can be temporarily placed. This way, the nesting can be optimized. It also enables the combination of different materials into one laminate, by storing the plies until all required materials are cut and available. The system is equipped with a vision table that can check the quality of the cut plies, increasing the accuracy of placement to the required level.

The preforms have a maximum size of 3.5m. Airborne will enlarge the size of its standard system to accommodate these large plies.

Airborne uses software-driven automation. The user can easily upload new nest files, ply shapes or laminate definitions and the system will adapt automatically.

In this project, Airborne will develop further its APP system to Airbus requirements, test and install the system in the factory, before handing it over to Airbus. An extensive trial period is included in the project, to ensure the system can reach the required accuracy and robustness that is needed for the highly loaded and critical primary structure components. Airbus will support Airborne and qualify the technology to be used according to its standards.

This joint project is an example of the collaboration between the Netherlands and Airbus, where the bottom-up R&D development that started years ago at fundamental level is now resulting in qualification of the process for primary aircraft structure.

Marcus Kremers, CTO of Airborne, says, “We are extremely proud to be able to supply Airbus with our APP technology. It is great that our vision on creating new methods to automate composite manufacturing is shared and that we can bring this exciting technology into the heart of Airbus composite manufacturing in the Getafe plant.”

Watch a video of the Airborne Automated Preforming system for Freeform Tailored Blanks.

Latest from Aerospace Manufacturing and Design

- TMTS 2026 explores AI-powered sustainable manufacturing and more

- Expanded line of blind-hole and through-hole taps

- EMCO Corp. opens state-of-the-art showroom

- Expanded two-axis laser scan head line

- The latest workholding technology to boost productivity and efficiency

- There’s still time to register for our 2026 Manufacturing Forecast roundtable!

- Vertical Aerospace brings Valo to New York

- Industrial display for enhanced HMI, visualization