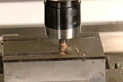

Since its release in early 2009, the CoroMill 316 EH (Exchangeable Head) milling system has been adopted by a large number of American aerospace manufacturers. To further increase the value received by these companies, Sandvik Coromant has developed a range of EH integrated toolholders that enable a much shorter tool overhang. Their innovative design provides a more secure performance when compared to a cylindrical shank tool clamped in a collet chuck or precision power chuck, with no detriment to torque transmission, run out or accuracy.

Some of the key aerospace applications to benefit from the EH integrated toolholders include slot, shoulder, corner and profile milling of different frame structural components. Additionally, the new solution offers increased productivity in engine components, such as scallop milling of turbine discs, blisks and engine shafts, as well as roughing slots for titanium blisks and impellers.

Obtaining optimal machining results requires minimizing tool overhang. This often proves challenging for aerospace components that demand long reaches, but cannot accept a sacrifice of accuracy or precision. The EH system allows for the shortest possible programming length, providing a much needed increase in stability and enhancing productivity when all other machining parameters remain unchanged. The reduced run out also boosts tool life, increasing component quality.

The key to the success of the EH tools and toolholders is the innovative mechanical connection between the carbide head and tool shank or integrated holder. The coupling consists of a self-centering screw containing a specially developed thread with saw tooth profile that pulls the head into the shank. The thread is pre-tensioned to eliminate the possibility of play within the connection. The design offers generous axial support face, as well as a tapered radial support face, while the inner end of the head screw is supported of the location hole to provide high bending strength.

With the EH system, an Allen key loosens and tightens the head, allowing full replacement in less than 15 seconds. The unique interface between the carbide head and shank or integrated holder offers stiffness sufficient for milling operations ranging from full-slot roughing to high accuracy finishing. Axial tool length repeatability and radial tool run out are held within a few hundredths of a millimeter.

The modular design of the EH system enables many tooling combinations to suit specific applications and machine tools from a relatively small inventory of standard items. This allows a single EH integrated holder to replace a separate precision chuck and cylindrical shank tool, reducing inventory costs in addition to providing increased performance.

To make the benefits of the EH system available to as many manufacturers as possible, 72 EH integrated toolholders are offered, spanning all common couplings and machine types. The range of carbide heads for the EH system includes twin-blade and multi-flute cutters, as well as heads with 40? and 50? helix angles to maximize machining stability. Cordell-type cutters, high-feed roughing cutters and ball nose profiling cutters are also available as variants. The EH system can be used for applications from high feed face milling, slot milling and helical interpolation to shoulder milling, profile milling and chamfer milling and is applicable to material groups from ISO-P through ISO-S.

By: Henri Sevonen, Program Manager, Aerospace, Sandvik Coromant

Latest from Aerospace Manufacturing and Design

- The Lee Company opens Innovation Center

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family