Unlike the planes themselves, the machinery used to make aircraft fasteners, until recently, was way behind. In fact, the majority of the threads from 3/8"-16TPI up to 1"-20TPI were rolled on three die machines of a basic design that was first built in 1942, and has changed little since inception. However, as Kinefac engineers began to examine what was needed to broaden the Kine-Roller product line, engineers quickly became aware of the needs of potential Kinefac users in this high quality threaded parts business.

As builders of two cylindrical die thread rolling machine systems, one of the first challenges was to eliminate the factors that made their setup more difficult than a three die threading application. The first customer who brought that complaint to Kinefac was producing threaded rod ends that required a special setup of the rolling support blade with respect to the rolling centerline to prevent crest scuff and flank laps. The MC-10 Kine-Roller with its fixed horizontal rolling centerline, which changes height during die penetration, did not lend itself to repeatable numerical adjustment. In addition, as the work support blade wore it abraded the thread crest. If the head of the bolt was heavy, a part hold-down device was required to assure a stable start. In rolling titanium, any instability of the blank axis of rotation during initial contact with the dies could create a drunk thread and related flank lapse.

At this point, based on lab and field experience, Kinefac engineers concluded that a different rolling support system was needed to get predictable rolling results.

At the same time, an aerospace fastener manufacturer, who was rolling short screws for skin attachments, came to Kinefac and said that he would far prefer a rolling system with a vertical axis to improve control of the rolling conditions and simplify manual loading. He wanted to have a rolling tool that would make it easier to position the workpiece on the rolling centerline. He also requested that we apply our Kine-Glide high hardness, low friction support blade in this setup.

Parallel to this, another company that makes some aerospace fasteners, industrial bearings, and components acquired the first of the MC-15 FI (V) CNC PowerBox Kine-Roller machines. Their initial experience showed that this new PowerBox high stiffness structure could readily handle the rolling force necessary to roll up to M16 X 2 up to 4-1/2" long at Rc35. To effectively use that rolling load capacity, engineers added the Autocentric work support tooling to future MC-15 Kine-Roller machines. With it a pneumatically actuated blank stabilizer blade, it maintains the blank against the work support blade until the dies take control. Then it is retracted to clear the finished thread O.D., allowing the part to be easily retracted from the rolling position. It worked so well that engineers decided to add it to all vertical PowerBox Kine-Roller machines that would be used for thread rolling.

Furthermore, the MC-15 FI is typically sold with full NC control of both spindles and the hydraulic die actuation, allowing the user to automatically rotary match the dies and control the die actuation, while integrating it with the die penetration.

Robotic Integration

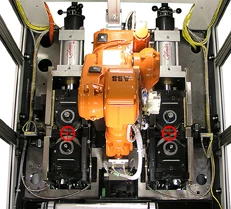

Prior to the introduction of the vertical axis PowerBox system for the aerospace industry, one of Kinefac’s automotive customers was using an MC-25 FI Kine-Roller to make ball studs in large quantities with a two step, two machine rolling process. In their system, they first rolled the thread and then transferred the part to a second machine for the roll finishing of the ball. When others became aware of the ease with which two MC-15 Kine-Roller machines are easily mounted on a common base with an integrated robot to perform the two rolling operations needed for a finished ball stud, the customer immediately decided to purchase such a machine. This provided the impetus to introduce the robot two machine integrated Robo-Roller to the aerospace industry. At the same time, the integration of the robot to the MC-15 FI Kine-Roller provided a cost effective method of warm rolling. In this simple application, the robot grasped the blank from an input track or tray, heated the area to be rolled, rolled the thread, and deposited the completed part in an output trough for cooling.

As customers saw the ability to use the robot for a variety of pre-rolling operations including the blank inspection, they began to acquire the MC-15 FI (V) CNC PowerBox Kine-Roller with an integrated robot. Still to come was another user’s desire to take that same MC-15 aerospace fastener system and add a fillet rolling station. As a result, engineers are now combining an industry standard three roll fillet rolling unit in another location in the robot path.

Multi-Operation Systems

With each of the above steps, we were moving closer to what has turned out to be a versatile multi-operation system in which the primary operation is the rolling of the thread. A variety of pre-rolling and post-rolling operations can be included in the system as required.

The Kinefac Automated Fastener Production System provides the user with major opportunities to improve the quality of the threads or rolled form, to decrease the process time, to measure blank diameter, to remove oversized blanks, to heat and roll the thread, and even to measure the finished part. By such process integration, the system can provide production improvement and cost reduction for the fastener manufacturer.

Addressing Costs

In reviewing these system capabilities with potential customers, it became clear that the market would significantly expand if further decreases in the costs of the system elements were available. Analysis showed that the major cost factor was the construction of the rolling machine and the second was the cost of the robot. As a result, engineers took customer input on the size and character of the machines they would like to see in the system described above if it used primarily for smaller parts. Since the majority of the fasteners (by piece) were 12mm in diameter or below, with thread lengths of 25mm and below, and a material hardness of Rc35, the MC-8 PowerBox Kine-Roller was designed and built. All of the key features of the MC-15, with some additional features directed toward the efficient rolling of the smaller threads, were incorporated, featuring a 19,000 lb radial die loach capacity.

The primary difference was the incorporation of a spindle system that had no outboard bearings. This was necessary because in the smaller size ranges a significant percentage of the fasteners have minimal body lengths. The design focused on the ability to use either the manual loading or robotic loading, but in all cases, it was desirable to locate the dies as close as possible to the part feed area while at the same time making it easier to adjust the auto-centric blade system from the top of the machine.

In order to keep the overall size of the machine smaller, the actuation cylinder was moved to the inside of the PowerBox and relocated in such a way that the centerline of the cylinder passed through the centerline of the die face. This was done to minimize any eccentric loading of the piston and simplify the need for phasing adjustment after matching the dies. For further conservation of space, all of the electrical, hydraulic, pneumatic, and mechanical adjustments were located on the basic machine structure. This made it possible to locate the MC-8 FI (V) PowerBox Kine-Roller into existing production lines or to use it as a portable machine with its own automatic ejection and cycle control. With respect to the Kine-Trol system, the electronics were virtually identical to those used in the MC-15, whether it is a full CNC-type machine or a mechanical-hydraulic machine. This concept was adopted based on the growing use of the standard Kine-Trol control system for virtually all of the CNC machines currently produced.

The manufacturing advantages and cost reduction benefits from the MC-15 were also realized in the MC-8 FI PowerBox Kine-Roller design. As a result, the prototype machine was built and tested, with the balance of the first batch of this machine model was shipped on October 1, 2010.

As the capabilities of the first two machines in this vertical axis infeed rolling machine series has found significant potential in the international marketplace, an Asian user of our MC-15 FI (V) PowerBox Kine-Roller has indicated that there is also a need for a larger capacity rolling machine of the MC-15 type with the same advantages we have described above. This machine designated the MC-40 PowerBox Kine-Roller would have a radial die load capacity of 90,000 lb and would embody all the basic features except for overhung spindles that are incorporated in the MC-8 and MC-15. They would naturally be enlarged to carry increased loads.

Kinefac recognizes that it may not have as large a customer demand as the smallest of the machines but there is no question in our mind that it has an important place in the production of aircraft fasteners up to 1-1/2" in diameter. Finally, Kinefac has seen rapid market acceptance of a single machine design but never before encountered a mach 4.8 customer acceptance. This experience has further confirmed the belief that major investment at the basic machine specification and design phase ultimately pays off in faster customer acceptance in the production area.

Kinefac Corp.

Worcester, MA

kinefac.com

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools