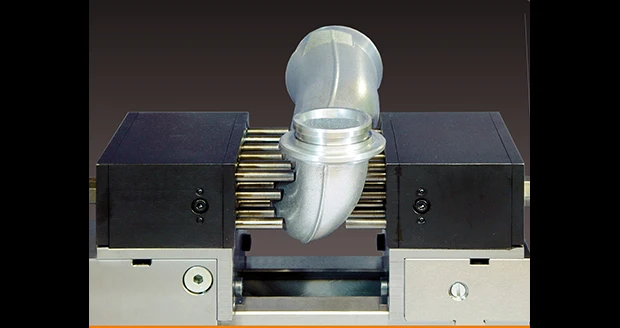

Menomonee Falls, Wisconsin – A part-specific outline is molded within seconds with this new flexible pin-clamping system, making your piece ready for machining, inspection, or numerous other applications. Each pin is locked hydraulically using separate, internal KOSTYRKA clamping sleeves with no axial or radial pin movement while locking. There is complete enclosure with no chip penetration and vibrations are reduced.

The JAW provides a wide range of different fields of application starting with the machining of cast parts, free-form surfaces, and prototypes to solutions for the assembly. It can be customized with an almost unlimited number of pins. Automation is possible. These elements can be used as jaws for vices, as supports, in combination with robot grippers or in any variety of custom-made solutions.

Source: Euro-Tech Corp.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators