The example of Brisker, a busy machining job shop in Vienna, Austria, contradicts the idea that EMCO Maier machines are strictly used for training and acncillary purposes. Using nearly 20 EMCO Maier machines, which include the EMCOTURN 332, HYPERTURN 665 and HYPERTURN 45 produce thousands of parts a week.

The example of Brisker, a busy machining job shop in Vienna, Austria, contradicts the idea that EMCO Maier machines are strictly used for training and acncillary purposes. Using nearly 20 EMCO Maier machines, which include the EMCOTURN 332, HYPERTURN 665 and HYPERTURN 45 produce thousands of parts a week.

The success story of Brisker GmbH started in 1950 when Johann Brisker Sr. founded the company as a traditional metalworking shop. The company's early activities included all aspects of metalworking and machining. However, under the current president, Johann Brisker, it has specialized in the manufacture of precision turned and milled parts.

The company's 25 employees, who work on an 800m² shop floor, act as suppliers to all industrial sectors. They mostly produce small or microparts in series running from 50 to 5,000 pieces in all standard materials, such as stainless steel, aluminum, or titanium. Complete assembly of individual components is also available upon request.

Key machine tool requirements at Brisker include:

• High productivity for series production

• Complete machining from bar stock

• Y-axis and driven tools

• Compatibility with existing tool holders

• Interchangeability of existing clamping devices

• Compact dimensions incl. bar loader (short bar loader)

• Siemens control compatible with the existing machine pool

• Competent and reliable customer service

"For this range of parts in particular, there is simply no comparable two-spindle machine on the market that offers such a high level of precision from such a small footprint," says Brisker.

EMCO customer from the outset

In the field of turning in particular, there is a strong drive to manufacture parts in line with the current state of the art. Which is why Johann Brisker bought the first EMCOTURN 320 in 1987. The company president was so pleased with the machine that he went on to purchase nine EMCOTURN 332 with counter spindles and two turrets.

All turning machines were automated with (short) bar loaders in order to meet the high requirements posed in terms of cost effectiveness.

Over the years, the two companies came to view each other as partners: "Since we work relatively closely with EMCO, we often see ideas that originate from our longstanding experience in the manufacture of precision turning parts being incorporated into the new machine models manufactured by EMCO. This is something of which we are particularly proud," says Brisker.

When the company needed an additional CNC lathe for a specific size of parts in 2009, it once again approached EMCO with its particular needs. Following the positive experience of "complete machining" using two HYPERTURN 665 from EMCO, Brisker decided that the most important criterion was complete machining from bar stock.

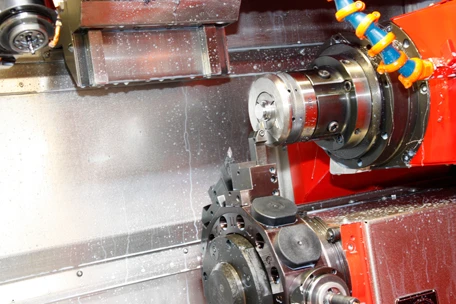

Although the market for this is not exactly flooded with models, especially at the smaller end of the parts spectrum, EMCO had recently launched its HYPERTURN 45, which provided the ideal solution for the range of parts required at Brisker. This new counter-spindle machine features two turrets, driven tools on both turrets and a Y-axis, all combined in an extremely space-saving form.

A quick look in the production floor of Brisker highlights the importance of the latter factor for the company. "Our machine hall is designed and planned down to the very last corner," explains Johann Brisker, "which means that a compact machine footprint is always one of our key criteria."

A quick look in the production floor of Brisker highlights the importance of the latter factor for the company. "Our machine hall is designed and planned down to the very last corner," explains Johann Brisker, "which means that a compact machine footprint is always one of our key criteria."

A further advantage of using the same or related machines with the same control technology is program compatibility. Since Brisker continues to use workshop programming for turning, this has certain benefits for the flexibility of the machine pool. However, this was not the only reason why Brisker decided on the HYPERTURN 45. The company president was also impressed by the hard technical data.

Increasing Productivity Through Technology

The most striking aspect of the HYPERTURN 45 is its small and compact construction, which conceals a surprising degree of technology: high-performance main and counter spindles, two turrets for up to 12 tool adapters, water-cooled, integrated spindle motors, dynamic digital drives, and thermo-symmetrical machine construction.

One great benefit of the HYPERTURN 45 over the EMCOTURN 332 is a Y-axis with a 70 mm traverse path in the upper slide system and a Z2-axis in the lower slide system. As with the HYPERTURN 645/665, the main and counter spindles are equipped with integrated, water-cooled spindle motors with drive power of 15 kW, a maximum speed of 7,000 rpm, and torque of 100 Nm.

"The high dynamics mean that we have to install harder vibration dampers and screw the machine to the floor at four points, rather than just two," explains the company president.

The spindle length of the HYPERTURN 45 was adjusted to match the short loader magazine. "It can process the typical bar stock of 1m without the need for an additional support," says Gerhard Nebohy, EMCO sales engineer.

The large dimensions of the counter spindle connection with A2-5 enable the counter spindle to be used to remove barstock parts with a diameter of up to 45 mm, while the latest control and drive system, Siemens 840D-sl (solution line), makes the machine quick and easy to program. When coupled with the CAM solution Esprit from DP Technology, the HYPERTURN 45 becomes a high-tech production center with 3D simulation.

Johann Brisker also has a specific example to demonstrate the system's outstanding technical performance: Complete machining of a workpiece with a high level of milling content (approx. 50 percent) on the EMCOTURN 332 lasts around three minutes, which is already a good time. Without any program optimization, the HYPERTURN 45 has already reduced this machining time to under two minutes - representing an improvement of around 35 percent.

"For parts with a large number of turning operations, the average increase in productivity is 20 percent,” Brisker said. “This has been achieved solely through the significantly higher dynamics, faster rapid traverses, and reduced tool changing times."

Service levels influence purchasing

Johann Brisker is also extremely happy with the service reliability and after-sales support provided by EMCO: "It's one of the main reasons we decided on EMCO.

The availability of spare parts and the company's response times are exemplary."

He is also full of praise for the ergonomics and design of the system: "Ergonomic considerations in particular, such as locating the spindle and turret within easy reach of the machine operator, are essential for fatigue-free operation. The EMCO design is extremely well thought out in this regard."

Excellent value for money

"We don't just blindly buy EMCO out of habit - we also use CNC machines from other manufacturers. However, for this range of parts in particular, there is simply no comparable two-spindle machine on the market that offers such a high level of precision from such a small footprint," says Brisker, who is clearly likes the HYPERTURN 45.

"Our customers aren't just interested in increasing productivity. They also want backward compatibility with existing NC programs and often have large quantities of tool holders and clamping devices that need to be reused," pointed out Gerhard Meisl, EMCO Senior Product Manager.

EMCO

Salzburg-based EMCO is one of Europe's leading machine tool manufacturers. Its two commitments "Made in the Heart of Europe" and "Design to Cost" are the main factors in the success of the international company, which represents excellent production quality and functional design. EMCO is part of A-TEC Industries AG and currently employs around 800 staff at a total of 4 production facilities in Austria, Germany and Italy.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools