In conjunction with the General Conference on Weights and Measures (CGPM), the kelvin, the basic unit of thermodynamic temperature, is currently being newly defined at the PTB (Physikalisch-Technischen Bundesanstalt) in Braunschweig, Germany, the counterpart of NIST in the US. The goal of PTB's portion of the program is a precise determination of the Boltzmann constant k, the conversion factor between thermal and mechanical energy. The project is being done with the help of a highly accurate reference formtester from Mahr, the MarForm MFU 110 WP, which includes both tactile and optical sensors, and provides accuracy into the nanometer range.

In October of 2011, the CGPM adopted a plan to redefine four of the seven base units of the International System of Units (SI) in terms of the invariants of nature - the fundamental physical constants or properties of atoms. A previous example of this was the redefinition of the meter in 1983, which links it to an exact value of the speed of light in a vacuum. The Conference recommended that efforts be made by the various National Metrology Institutes to reduce the uncertainties of these constants.

The CGPM also noted that, "The kelvin is currently defined in terms of an intrinsic property of water that, while being an invariant of nature, in practice depends on the purity and isotopic composition of the water used." Instead, the Conference suggested that it was "possible to redefine the kelvin so that it is linked to an exact numerical value of the Boltzmann constant k," which links temperature to mechanical energy.

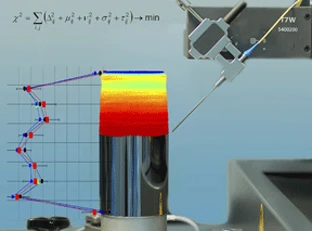

As part of their work to precisely determine the Boltzmann constant, PTB needed to define absolute helium pressures. These were realized with the help of a pressure balance, the essential components of which were piston-cylinder systems. For the precise calculation of pressure, the geometry of the pistons and cylinders at ambient pressure had to be known exactly: hence, PTB's use of the reference formtester from Mahr. This highly precise reference unit is the world's leading instrument for tactile distance and diameter measurements in the measuring range of up to 180mm.

PTB used the White Point optical stylus system on the MarForm MFU 110WP to measure the pistons and cylinders. White Point is an optical (interferometrical) stylus system for form measuring machines which allows form and diameter measurements of precision mechanical parts with tolerances of less than 1µm. The optical system is based on a novel concept of short coherence heterodyne interferometry working with two wavelengths. Typical parameters are roundness, straightness, parallelism, angle and diameter. The small optical probe allows fast non-contact measurements of very small and hard-to-access geometries, and provides optical contact at two different angles.

The first approach to the calculation of the measurement uncertainty of the generated 3D geometry data showed that the dimensional 3D standard measurement uncertainties only amounted to 7nm for the piston and 15nm for the cylinder. This results in a relative measurement uncertainty for the cross-sectional area of 0.7 x 10-6, which may well contribute to decreasing the measurement uncertainty for the Boltzmann constant as a whole.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators