Exact Metrology

Exact Metrology: A Division of In-Place Machining Company, a comprehensive 3D metrology service provider and hardware sales company, has recently seen an uptick in requests for scanning large aerospace components. Greg Groth, division manager at Exact Metrology’s Brookfield, Wisconsin location shares his thoughts on this development.

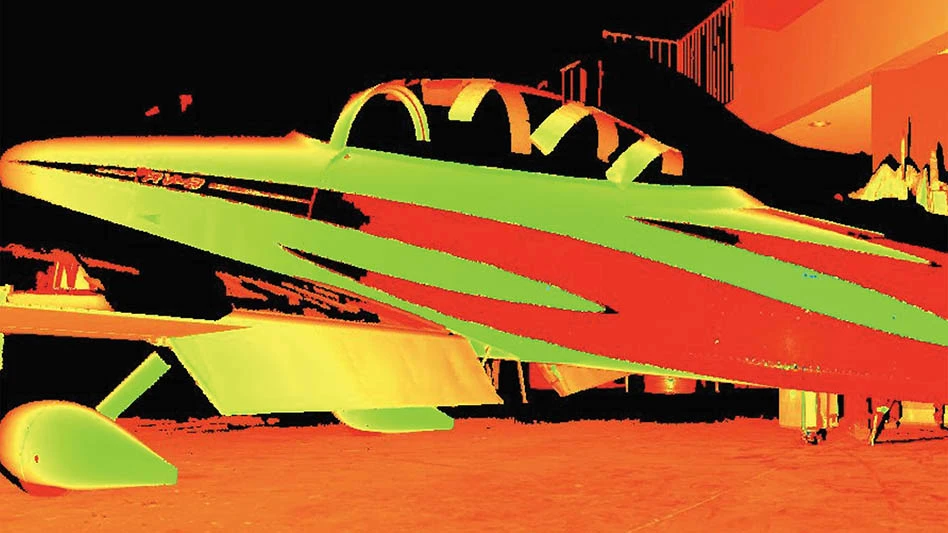

It’s widely known that the aerospace industry has long been a driver of 3D scanning and the implementation of this technology into quality systems. When speaking of the surge in interest in scanning from aerospace customers, Groth said, “As the scanning technology’s accuracy has improved and data collection has become much faster, the viability of scanning full vehicles or component-level parts has seen a dramatic increase in demand.”

For example, scanning an airplane exterior can now be completed in a matter of days when, in the past, it would take up to a week. Additionally, data processing has also become much quicker with advancements made in software and data handling. Groth added that he has seen the number of full aircraft scans nearly triple in the last year at his company.

Metrology, Brookfield, Wisconsin

For scanning projects of this size, Exact Metrology uses a combination of laser trackers and long-range scanners. The use of these high-precision metrology instruments allows quick scanning of large volumes as well as control of the scan-to-scan for fit and accuracy. Additionally, the alignment challenges that have long been present in the aerospace industry have been greatly reduced with the innovative capabilities of both laser trackers and today’s long-range scanners.

With aluminum continuing to be the most often used material in manufacturing aerospace skins and components, advancements made in metrology instruments now allow for highly accurate scanning both indoors in an environmentally controlled condition and outdoors when conditions are less than ideal. Newer technology can combat both the high reflectivity of chrome finishes and material expansion.

Due to scale, the metrology instruments used by Exact Metrology can vary. Groth commented that the same level of precision may not be required for a full body scan as the required specifications for panels or component-level details. For these tight tolerance areas, Exact Metrology will use higher precision scanners such as portable coordinate measurement machines (PCMMS) or structured light scanners.

Fastening of components and structure sections is also critical. Exact Metrology specialists can leverage several different pieces of equipment with the current bandwidth of metrology hardware. For example, if off-vehicle and internal structural information is needed, computed tomography (CT) scanning can be used. CT scanners can assess a clogged fuel line or a small manifold, for example, including evaluation of cracks or manufacturing imperfections such as porosity.

Discussing the importance of having highly precise and accurate inspection data for the aerospace industry, Groth said, “The precision we’re achieving on scans allows for more accurate duplication in reverse engineering applications, while the precise representation increases the confidence in part validation on the inspection. Accurate representations allow for more improved virtual testing such as finite element analysis (FEA) or any flow-based testing.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Latest from Aerospace Manufacturing and Design

- GE Aerospace demonstrates narrowbody hybrid electric engine

- 1, 2, and 3-axis standalone motion control systems

- TMTS 2026 explores AI-powered sustainable manufacturing and more

- Expanded line of blind-hole and through-hole taps

- EMCO Corp. opens state-of-the-art showroom

- Expanded two-axis laser scan head line

- The latest workholding technology to boost productivity and efficiency

- There’s still time to register for our 2026 Manufacturing Forecast roundtable!