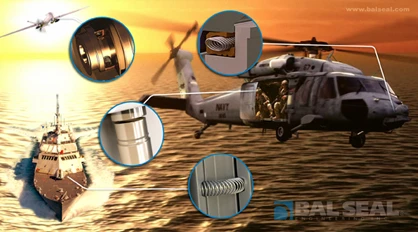

Using photorealistic images of military and commercial aircraft, a naval vessel and a satellite, the four-page “TMB-11” describes how the company’s precision-engineered Canted Coil Spring is employed as a seal energizer or stand-alone electrical-mechanical component to improve overall equipment performance and reliability. The guide can be downloaded free of charge from the company’s online technical library at http://www.balseal.com/files/tech_library/TMB11.pdf. Requests for free printed copies can be e-mailed to sales@balseal.com.

The Canted Coil Spring, a current-carrying, locking, latching and holding solution already at work in thousands of critical defense and aerospace applications worldwide, is available in a broad range of coil heights and materials. Its unique design enables it to maintain a nearly constant force over a broad compression range, compensating for large mating tolerances and temperature changes without significant deviation from its initial force. Each coil in the spring works independently, maintaining contact with the mating surface and ensuring maximum conductivity. The versatile component allows designers to engineer specific insertion and breakaway forces, and it also functions as an EMI/RFI shielding and grounding element.

When used as an energizer in seals made from PTFE, UHMWPE and other specially formulated polymers, the Canted Coil Spring ensures more even, consistent wear and longer service life in rotary, reciprocating, oscillating and static applications.

The new TMB-11 uses detailed insets and application callouts to provide the reader with a “virtual look” at where and how Bal Seal’s products work in aerospace and defense equipment. Featured applications include UAV actuators, optoelectronics gimbals or “pods,” hydraulic systems, solar arrays, and others.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools