Gibbs and Associates has announced that its suite of GibbsCAM modules supports SolidWorks 2011 3D CAD software with new capabilities to make geometry machinable and to generate NC programs for all configurations of mills and lathes, including Multi-task machines (MTM), Swissturn machines, and 5-axis machining centers. The GibbsCAM interface also helps the SolidWorks 2011 user by providing an easy-to-learn and easy-to-use interface developed with language and icons that manufacturing engineers, NC programmers and machinists understand.

SolidWorks 2011 optimizes core design functions so that users can more quickly and intelligently achieve their goals. It also includes hundreds of new enhancements specifically requested by customers. The new version of SolidWorks improves designers’ and engineers’ productivity with new capabilities like rapid dimensions, enhanced mirrored components, and heads-up mouse gesturing. These capabilities let designers and engineers work smarter and faster while minimizing menu navigation.

“Engineers, NC programmers and machinists don’t have time to worry about software complexity or the problem of integrating data between separate applications,” said Nick Iwaskow, SolidWorks Manager, Alliances. “Combining GibbsCAM’s CNC programming, toolpath verification, machine-tool simulation, and post processing with SolidWorks 2011 3D CAD enables engineers, NC programmers and machinists to focus on innovation, quality, and productivity instead of how to use the software.”

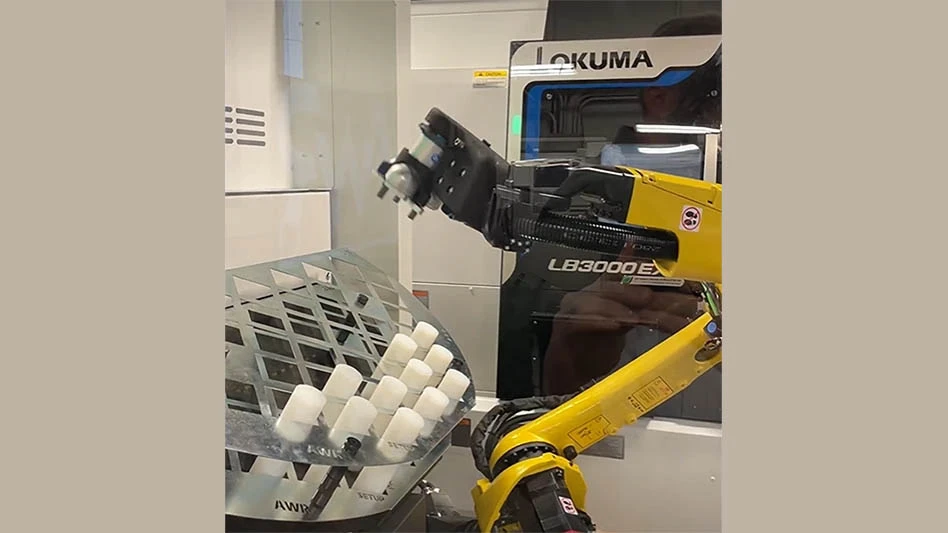

Manufacturing engineers and NC programmers will use GibbsCAM to generate NC programs for all types of CNC machine tools from design models created in SolidWorks software, with seamless transition. GibbsCAM opens SolidWorks models so that the NC programmer can analyze and optimize them for machinability, and generate toolpaths for the chosen or available CNC machine tool. GibbsCAM verifies the toolpaths with gouge detection and interference checking, then dynamically and visually simulates them on virtual machine tools, and accurately postprocesses them to generate optimal NC programs. The manufacturing engineer and NC programmer can use various GibbsCAM features to eliminate scrap, reduce cycle times, and maximize efficiency, safety and profits.

Latest from Aerospace Manufacturing and Design

- Nidec Aerospace establishes Atlanta hub to accelerate electric propulsion innovation

- Brochure for high-precision motion control, nanopositioning automation, piezo solutions

- Forecast 2026 Webinar

- America Makes announces two project calls worth $8 million

- Jaw force gauges

- Air India orders 30 Boeing 737 MAX jets

- Speed increasers for lathes, Swiss-style machines

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers