EOS

The aerospace industry has always been performance-centric and design-driven, focusing on trying and proving advanced concepts. In the past, the sector was mainly driven by government spending and legacy, established original equipment manufacturers (OEMS), as the costs and risks involved were too high. Risks that were once huge barriers for startups and smaller organizations are now gradually diminishing as more and more private companies enter the market. But how? Among other frontier tech, the adoption and availability of additive manufacturing (AM) has allowed innovations to test and thrive and for a start-up scene to quickly emerge in aviation and space tech. What was once only the domain of massive government and very long-term programs, has been entered by agile organizations built around AM and other emerging technologies.

Now the world is rapidly shifting to a connected, remote operations-dominated and largely post-pandemic mindset. Space exploration can shape the world of tomorrow technologically, investment-wise, and from an entrepreneurial point of view.

Today, the biggest and most profitable companies are in tech. Tomorrow, major businesses will rely on space-driven infrastructure to innovate. As every major company today is a tech-based company, every major company in the future will be a space-based company. We’re already seeing the first steps of this play out. Space is not just a destination anymore, it’s an infrastructure for tech to innovate upon. From AWS Ground Station to Azure Orbital, each Facebook, Apple, Microsoft, Google, Amazon (FAMGA) company has an existing or emerging space initiative.

So why should smart and responsible organizations contribute to shaping this transformation and take advantage of the AM opportunity with infinite possibilities? Here’s why.

Increased access to manufacturing

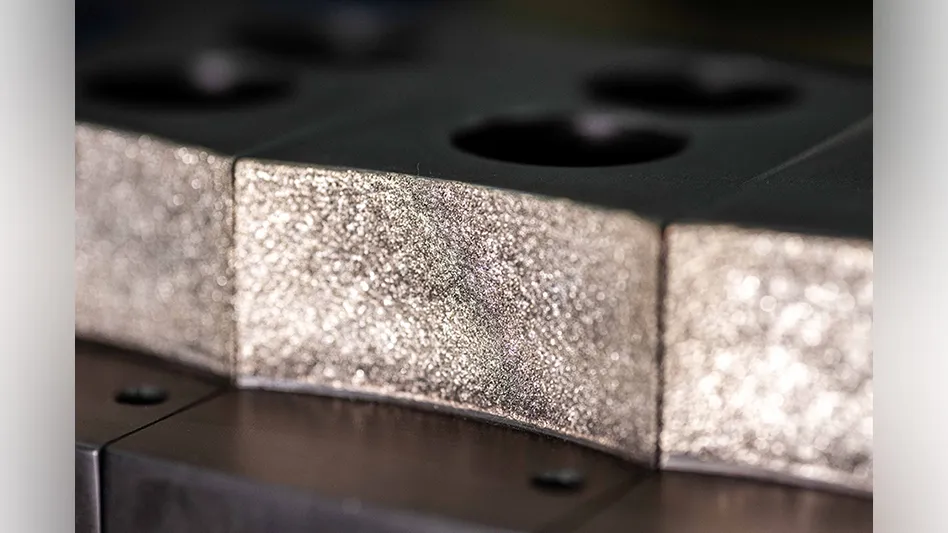

Before AM came into play, manufacturing constraints slowed down or stopped innovative solutions, yet the ultimate goals in aerospace remained: pushing performance and the boundaries of iterative thinking – with a relatively fast turnaround time. The new space industry demands performance and design-driven approaches such as integrated rocket cooling, or access to new material choices including combustion chambers with copper. The speed of proving these concepts and then getting these parts to market using AM is a key differentiator. Now it’s design fast, produce fast, test fast, fail fast, iterate fast, succeed faster. The production and supply chain bottleneck that normally occurs in terms of trial and error was often too costly or not accessible for manufacturers. But AM parts give decision-makers peace of mind that when the concepts are realized, reliable manufacturing is achievable.

Reliable production quality and automation

The biggest pain point for aerospace executives is to be able to consistently deliver critical systems. AM allows substantially faster concepts to meet market needs such as a completely integrated combustion chamber and nozzle all without compromising the quality of the components needed to keep complex systems up and running. While lacking in the past, current in-situ quality control, automatic calibration systems support the technical requirements and dimensional accuracy needed to meet end-use performance in the aerospace industry.

Additionally, since AM technology is inherently digital, the most innovative companies in the world leveraging space technologies to maintain their competitive edge will be able to rely on digital end-to-end AM workflows that automate processes. By making the AM part design process more efficient, aerospace engineers looking to capitalize on the next cycle of innovation can be empowered to assess design options before a part is even printed.

Efficient process control

Another aerospace pain point is part/assembly complexity. The desired solution was integration, part reduction, which is a native benefit of AM. Multiple or dozens of parts can now be printed in one print – reducing costs, eliminating assembly, and changing or eliminating repair and maintenance in many instances. AM allows potential game-changing companies of all sizes to go from part-level qualification to process-level qualification. It’s taken years to establish confidence in the process and the qualification requirements. The aviation and space industry now has confidence in AM to produce safety-critical components, which are of the utmost importance in such a regulation-heavy sector.

Commercial and easier access to space transportation services – enabled by advanced AM technologies – is leading to innovations that are just now emerging and will dominate the business world of tomorrow. Many critical building blocks of the aviation and space industry are being transformed almost irreversibly by AM – there shall be no looking back to conventional designs and manufacturing technologies.

About the author: Vinu Chaprayil Vijayan is GAM Aviation & Space at EOS.

Latest from Aerospace Manufacturing and Design

- Bell reveals Aircraft Laboratory for Future Autonomy

- Autogrip Machinery’s SP-324 stationary three-jaw chuck

- Sierra Space Dream Chaser reaches pre-flight testing milestone

- ABB's modular large robot portfolio

- #35 Lunch + Learn Podcast - How to use Autodesk Fusion with TATA Technologies

- UPCOMING WEBINAR: Additive Manufacturing for Aircraft Cockpit Interior Components

- Still time to register for the May 16 Manufacturing Lunch + Learn

- NIAR to add electric aircraft test capability