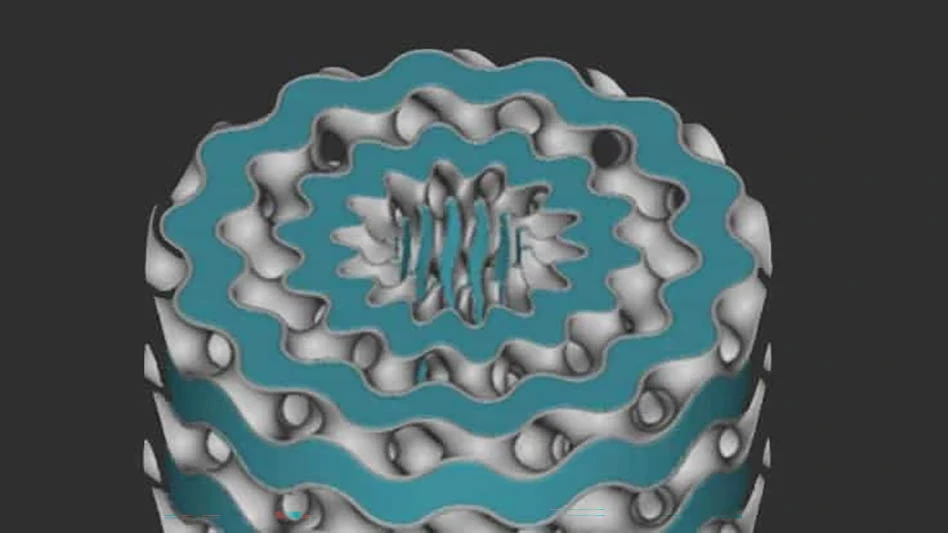

Phot credit: nTopology

It is now possible to produce a next generation high-performance Heat Exchanger (HEX) for the aerospace industry using advanced materials and manufacturing methods.

In aviation, thrust is required to propel air and spacecraft through the atmosphere. The engine combusts fuel and extracts mechanical work from this combustion to generate the thrust required for flight. In all engines, the process of combustion and mechanical work produces excess heat that must be dissipated. Specifically, the oil in the engine needs to be cooled to maintain the lubrication of components that rotate within the engine. In modern aircraft, the fuel spends much time stored in the wings, where it gets extremely cold. As such, it can be used to cool many of the subsystems of the aircraft. A Fuel Cooled Oil Cooler (FCOC) exchanges heat between the engine oil and the fuel in such a manner that the engine oil is cooled while the fuel is heated up. This exchange of heat serves two purposes: the cooled oil properly lubricates the engine while heating the fuel prevents the formation of ice crystals within the fuel.

Latest from Aerospace Manufacturing and Design

- CDT, DR. KAISER partner in grinding and dressing

- CT system for shop floor use

- North Aircraft Industries to manufacture Horizon Aircraft’s Cavorite X7 wings

- Automated surface finishing of 3D-printed parts

- C.R. Onsrud annual factory Demo Day is March 25, 2026

- Axial grooving system introduced

- Manufacturing technology orders set record in December 2025

- High-performance HV fuses