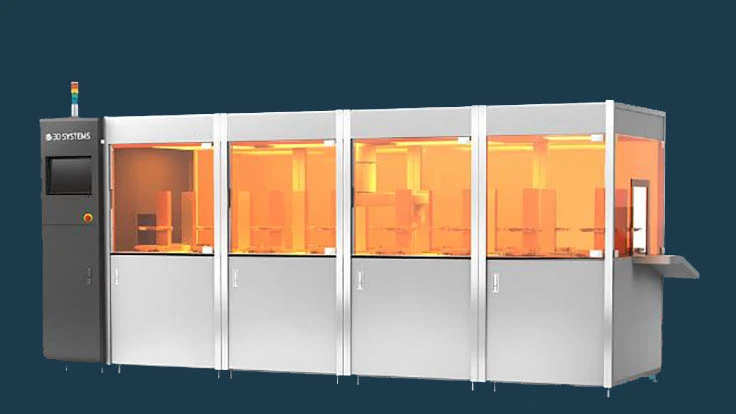

Chicago, Illinois – Delivering on its strategy to transform 3D manufacturing workflows, 3D Systems has unveiled a modular, scalable, and fully-integrated additive manufacturing platform. 3D Systems’ Figure 4 production platform produces plastic parts more than 50x faster than current systems, delivering lower total cost of operations while offering competitive and compelling comparisons to conventional methods.

3D Systems’ Figure 4 fully automated, high-volume, 16-print engine production solution allows customers to tailor configurations and select materials to address specific applications. Configurations range from single-print engine machines to fully automated, high-volume production systems with 16 or more print engines, automated material delivery, and integrated post-processing.

The company recently shipped the first system to a Fortune 50 industrial customer, and plans to ramp customer-specific shipments throughout the second half of 2017.

“We believe our breakthrough Figure 4 platform will revolutionize manufacturing by transforming production of both mass customized and complex end use parts with a compelling total cost of operations versus conventional methods,” said Vyomesh Joshi, 3D Systems’ president and CEO.

In due course, the company intends to extend the Figure 4 platform application by application to meet specific customer needs across healthcare, aerospace, automotive, and durable goods industries.

Source: 3D Systems

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators