All images courtesy Volume Graphics

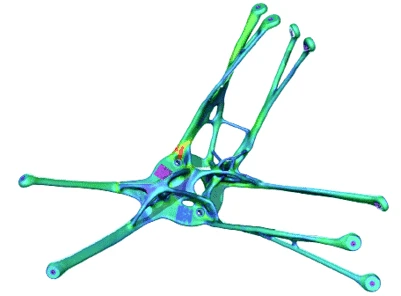

Qualifying parts for

aerospace takes on special significance when parts are 3D-printed. Metals and

polymers used to make 3D-printed components are essentially forged on the fly,

so there may be questions about material integrity that must be answered comprehensively

and scientifically. Especially with flight-critical parts, the technology used

to accomplish this task is computed tomography, better known as CT scanning.

Read the full article now!

Latest from Aerospace Manufacturing and Design

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification