By scharfsinn86 | © Stock Adobe

Aircraft original equipment manufacturers (OEMs) Airbus, Boeing, and Embraer, among others, have pledged to make their airplanes 100% SAF compatible by 2030. Although that’s more than six years away, it’s not much time to develop aircraft systems to ensure mechanical parts are fully compatible with the SAFs that’ll be available then. While numerous tests have shown aircraft can fly on blends of 50% traditional kerosene-based jet fuel and 50% SAF, only a few OEMs have demonstrated flying with 100% SAF. Aero-engine manufacturers CFM International, GE Aerospace, MTU Aero Engines, Pratt & Whitney, and Rolls-Royce can now operate their commercial and military aircraft engines with SAF at blends up to 50% with standard Jet A kerosene. The engine OEMs also are supporting industry initiatives to approve and adopt 100% SAF by 2030.

At present, there’s no one definition of SAF, which can be made from animal fats, vegetable oils, used cooking oils, cornstalks, algae, corn, woody biomass, crop residues – even winemaking waste. SAF can also be made from syngas processes – notably the Fischer-Tropsch process – using hydrogen and carbon monoxide derived from CO2 as feedstocks. The important difference is 50/50 SAF blends are considered drop-in replacements for kerosene jet fuel. However, 100% SAF hasn’t been validated as a drop-in replacement. One reason is kerosene, a petroleum fuel, contains in addition to paraffins, aromatic (ring-shaped) hydrocarbons with lubricating properties. Conventional jet fuels have between 8% to 25% aromatic content. SAF formulas today (50/50 blends) still benefit from aromatics in the conventional portion. However, 100% SAF, composed of all paraffinic (straight-chain) oils, has no aromatic content so it doesn’t offer the same lubrication and other benefits.

The difference is significant. Boeing Propulsion Systems Division and Fuels Technical Fellow J. P. Belieres says in the company’s Innovation Quarterlyfor Q3 2023, “Our systems and materials on our airplanes were designed for conventional jet fuels. Now that we’re moving to cleaner and more efficient jet fuels, which may not have some of the chemical compounds of petroleum-based jet fuels, we need to make sure our systems are compatible.” His list includes anything fuels contact on the airplane, including paint primers and finishes, sealants, metals, composites, fuel tanks, and O-rings.

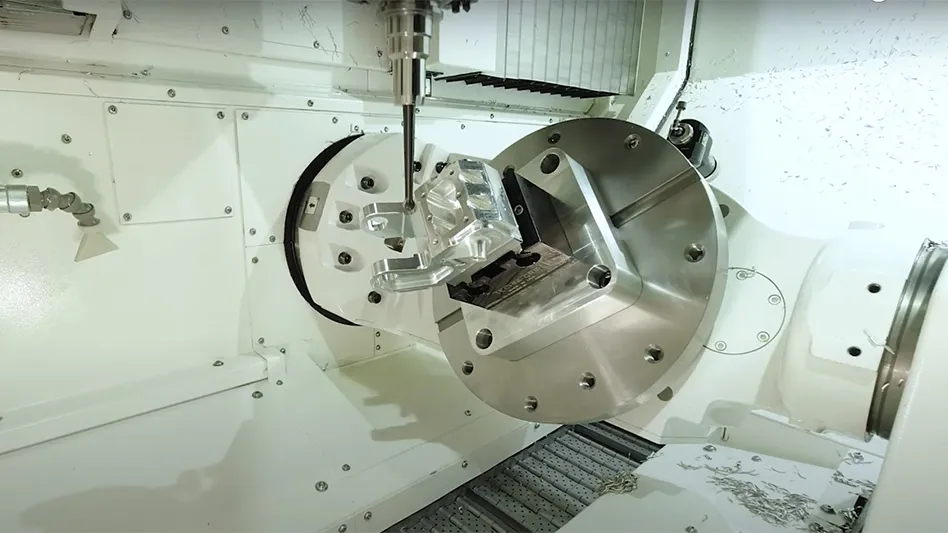

Fuel systems

Eaton is a fuel systems provider, developing fuel pumps on aero engines as well as within aircraft fuel tanks, fuel valves, fuel gauging systems that measure fuel quantity in the tanks, and fuel inerting for flammability reduction and safety. Jeff Skinner, Eaton’s director of engineering, Aerospace, shared some of the company’s preparations for making its components compatible with 100% SAF. While Eaton’s current fuel portfolio is compatible with drop-in SAF, engineers are evaluating how 100% SAF affects those products. Preliminary assessments of fuel systems products confirmed some expected effects of non-drop-in SAF. Skinner reported those findings at Eaton’s online Knowledge Center, among them:

- Eliminating aromatic content in non-drop-in SAF will require replacing nitrile-based seal materials

- Long-term impacts of SAF chemistry, such as non-aromatic or paraffinic oils, may have an unknown impact on non-metallic materials used within the construction of fuel pumps and aircraft fuel system equipment

- Pump performance at high climb rates and extreme temperatures will be impacted by fuel changes

- Fuel system longevity will be impacted by changes to cavitation properties due to bubble nucleation rates and shock transmissibility changes

- Reductions to the SAF fuel vapor auto-ignition temperature will require additional testing and may require modified thermal protection devices on aircraft equipment installed in the fuel tanks and adjacent flammable leakage zones

- Since SAF will be mixed with typical fuel additives, long-term effects due to corrosion and lubricity within fuel system equipment will be equivalent

Seals

Explaining these findings in a recent interview with Aerospace Manufacturing and Design, Skinner says for 100% paraffinic SAF with no aromatics, seals will have to be replaced. “It’s a solvable problem.”

He explains traditional nitrile seals respond to aromatic chemicals by swelling, which improves the seal. Without the aromatics, the seals tend to shrink, potentially introducing leakage.

“The solution is replacing nitrile with fluorocarbon seals,” Skinner says. The change can occur at the OEM or in the aftermarket. “The change is backwards compatible, so maybe future retrofit campaigns may include fluorocarbon seals instead of nitriles.”

Fuel gauging

Another component impacted by 100% SAF is the fuel gauging system. “Normally, fuel gauging on a commercial aircraft is done using a capacitive sensor, which requires calibration with the dielectric properties of the fuel,” Skinner says. “If the dielectric properties change due to a fuel mixture change, there’d likely have to be a recalibration of the system.”

Fuel pumps

Findings indicate pump performance at high climb rates to cruise altitude and extreme temperatures will be impacted by changes to the fuel. With 100% SAF, there’s a likelihood there’ll be a higher percentage of gas bubbles developing (measured in bubble nucleation rates), degrading pump performance and affecting the volume of fuel being pumped into the engine. “Integrated tiny bubbles can be a significant portion of the total volume flow,” Skinner says. “Anytime we certify a new fuel pump, we must show it’s capable of producing the required flows under all dynamic conditions, including high climb rates. We’re working with engine OEMs on this potential impact.”

Shock transmissibility changes are another concern. Skinner explains it’s the rate at which the fluid can compress. “It’s about dynamic pump performance. For a liquid, it’s straightforward – it’s going to be a function of the density. As bubble nucleation changes, and with it the potential for mixing gas within the fluid volume, the density changes,” he continues. “This makes the dynamic characteristics of the pressurization spongier. It’s a softer fluid. How that changes the pump performance is the concern.”

Asked if 100% SAF will influence pump design, Skinner says no. “The changes required; we don’t expect they’re going to have a material impact on pump core design.”

Fuel inerting

Eaton makes fuel inerting systems that monitor flammability and fuel safety. Skinner says they want to know the impacts the emergence of SAF will have on Eaton’s systems. “We’re seeing from the data sheets being provided about the various processes and the fuel composition, that the vapor ignition temperature is changing for some SAF.” Since there’s a potential change, Eaton engineers are investigating what the impacts may be.

Fuel system materials

Within fuel systems, there are coatings used on electric motor windings and tubing. “For tubing, normally there’s a protective surface on the inside. Again, the fluorocarbon solutions are well understood,” Skinner says. These internal non-metal coatings – and adhesives – must be evaluated for 100% SAF compatibility as well.

Future

Skinner is confident that what works for SAF in the future will continue to work in applications using existing conventional aviation fuels. So, while there may be changes required to accommodate non-drop-in SAF, those changes will be done in a way that tolerates any mix, up to 100% conventional fuel.

Skinner adds ASTM Int’l, the governing standards body for fuel composition, has a target of 2025 to define the acceptable parameters for non-drop-in SAF, based on industry needs and what’s possible. “For now, we’re responding to impacts that depend on the range of fluid properties we’re seeing in drop-in SAF.”

He is convinced any challenges 100% SAF poses to jet operations will find solutions. “Our industry deserves a lot of credit in its ability to assess impacts of changes like this.”

EatonLatest from Aerospace Manufacturing and Design

- UPCOMING WEBINAR: Additive Manufacturing for Aircraft Cockpit Interior Components

- Still time to register for the May 16 Manufacturing Lunch + Learn

- NIAR to add electric aircraft test capability

- Arnold Magnetic Technologies' custom electromagnetic capabilities

- Garmin earns best supplier recognition from Embraer for 9th consecutive year

- Dillon Manufacturing's Carbinite coating

- #43 Manufacturing Matters - 2024 Spring Aerospace Industry Outlook with Richard Aboulafia

- US operator UrbanLink orders 20 Lilium Jets