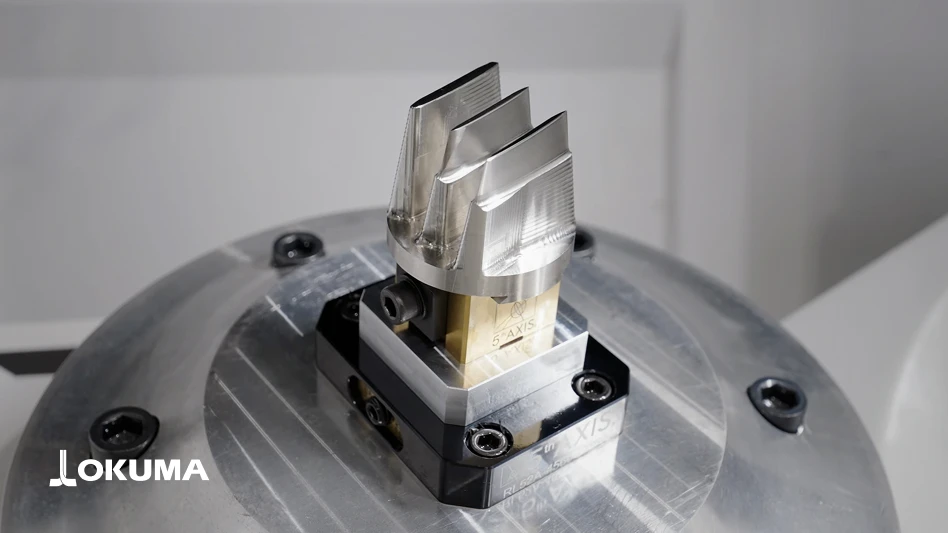

RCR relied on Okuma to achieve the extremely tight tolerances essential for aerospace in order to remain in compliance with the strict regulatory standards the industry required.

When Richard Childress Racing started looking to diversify the parts its shop was creating, they jumped at the chance to expand into aerospace, among other industries. An adjustment from their extensive background in motorsports, RCR relied on Okuma to achieve the extremely tight tolerances essential for aerospace in order to remain in compliance with the strict regulatory standards the industry required.Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools