Process optimization goes beyond optimizing a single tool or program, linking all machining operations together to evaluate the entire manufacturing process.

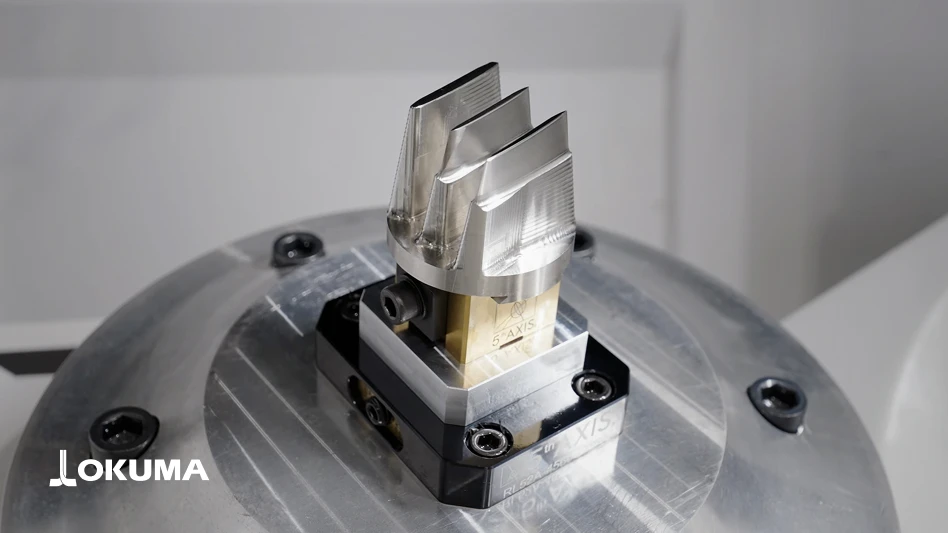

A digital twin involves 3D representations of the part, workpiece being machined, fixturing, cutting tools and NC machine, along with machine kinematics and CNC control functionality. Integration improves digital twin accuracy to raise the bar for simulating, verifying, and optimizing NC programs. This webinar looks at how using simulation software in this manner ensures NC programs are error-free, and that all operations work together as intended.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators