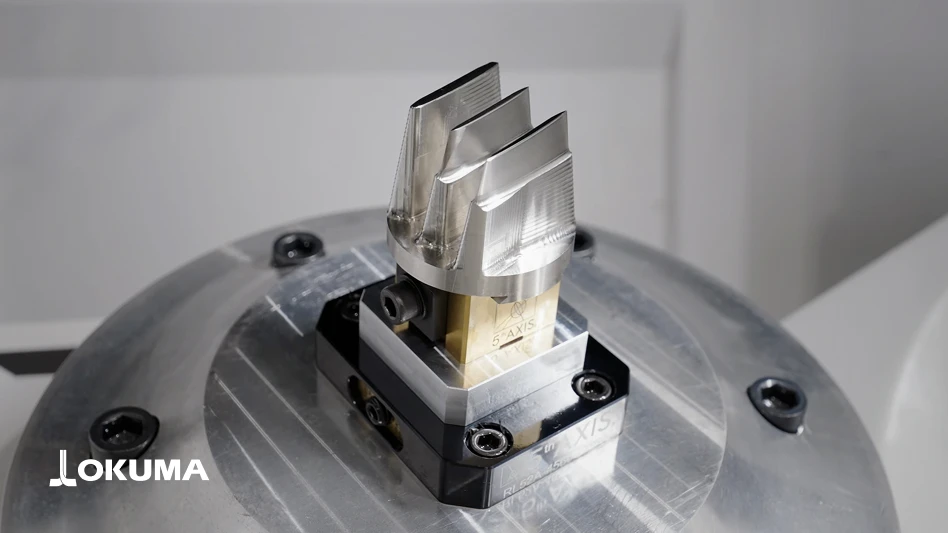

Okuma’s next-gen MB-5000HII horizontal machining center uses a revamped disc magazine for better floor space efficiency. Its ATC servo shutter allows for quicker tool change door opening/closing for shorter cycle times. The roller cam gear driving the B-axis gives more dynamic and fluid movements while modular way covers protect the machine’s internal components. An improved chip evacuation system reduces conveyor stoppages.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators