NSK America teamed up with our friends at DMG MORI USA and OSG Tool to try out our new CTS-3030 coolant through the tool spindle for micro drilling.

NSK America Corp. mounted the CTS-3030 on a DMG MORI NTX1000 and used the new OSG ADO coolant through drill (0.9mm diameter 5xD) to prove that when you have the high-speed capability to run the proper SFM, you not only greatly increase your productivity, you can still maintain tool life, hole concentricity and finish!

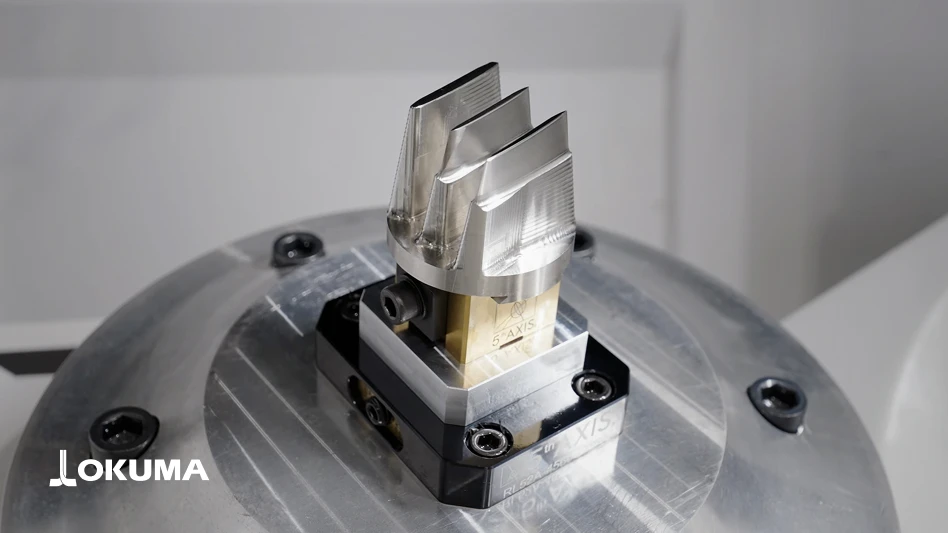

As you can see, we drilled more than 500 holes in 4140 alloy steel, 304 stainless steel, and 6Al4V titanium with double the productivity and virtually no wear to the drill. The through coolant & high RPM speed capability of the NSK spindle, combined with the excellent design features of the OSG ADO Micro Drill and rigidity of the DMG MORI NTX1000 offer you a winning solution for all your micro drilling applications!

The NSK CTS-3030 spindle system is powered by a 350W DC brushless electric motor for 24/7 operation and offers coolant through the tool for 2.0mm and smaller micro drills up to 20xD. Coolant pressure up to 2,900 PSI is possible with this system.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools