Sandvik Coromant specialists share best practices to meet these demands and introduce latest innovations made for machining difficult materials and aerospace parts.

As the aerospace industry shows continued recovery, cycle time reduction will become more and more critical to meet the increasing demands. The positive industry trends signal the need for new solutions to machine HRSA materials efficiently with maximum material removal, while predictably producing quality parts. With this in mind, Sandvik Coromant specialists share best practices to meet these demands and introduce latest innovations from Sandvik Coromant made for machining difficult materials and aerospace parts.

Learn:

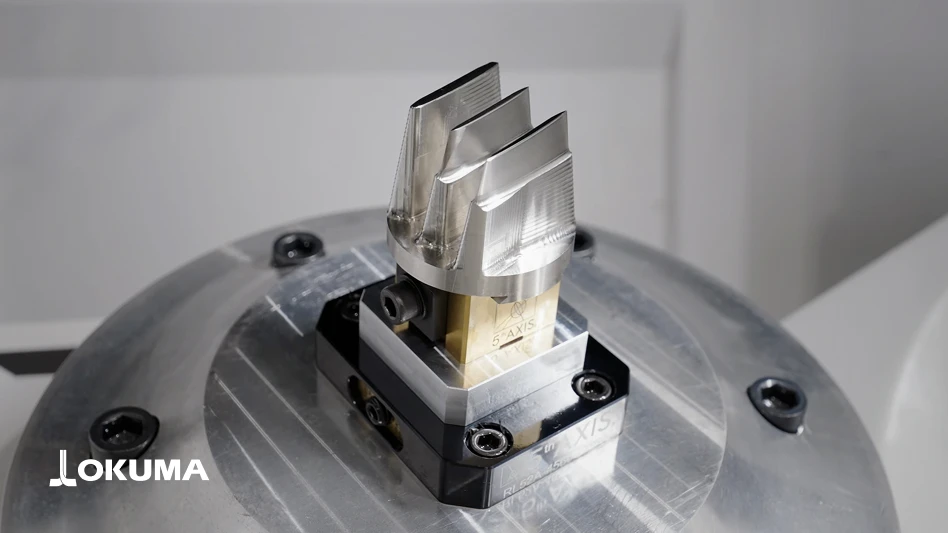

- How to boost process security when turning components –and how CoroTurn 107 stability makes it possible

- Why the new CoroMill MH20 is a powerful high feed pocket milling solution for ensuring secure and vibration-free machining

- How the new S205 HRSA turning grade for higher speeds increases productivity in semi-finishing and finishing applications

- The key solutions needed for productive turning of difficult machine materials in aerospace

Gain additional insight when you view the on-demand recording.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators