Learn a new approach and see how programming ultrasonic knife cutting with hyperMILL is easily accomplished and provides NC code simulation to reliably bring challenging 6-axis output to the machine.

Kevin Lewis, an Account Manager for OPEN MIND Technologies, USA covering the western region, explains how ultrasonic knife cutting represents an ideal solution for the efficient cutting of advanced materials including honeycomb, composites, and foams. Creating the required 6-axis NC programs (five machine axes plus a programmable spindle orientation) has historically proven a challenge.

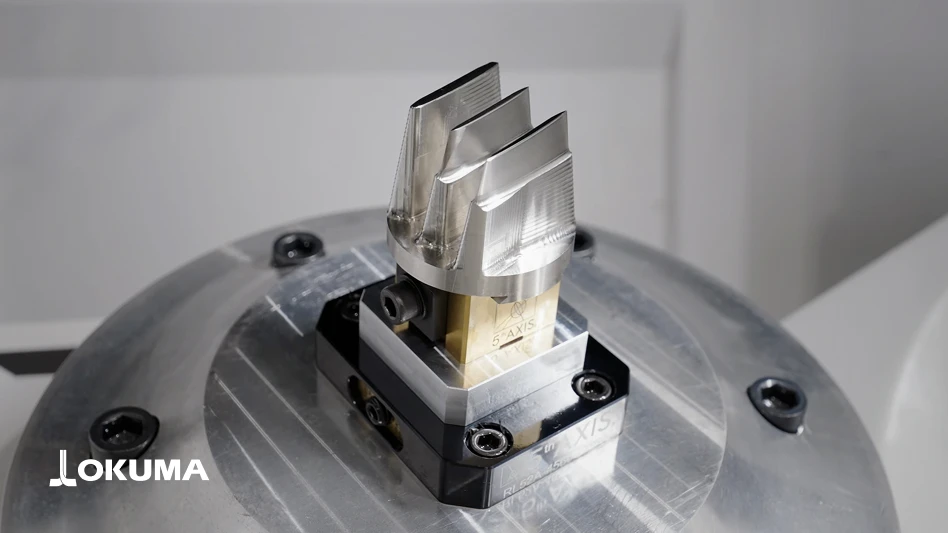

Learn a new approach and see how programming ultrasonic knife cutting with hyperMILL is easily accomplished and provides NC code simulation to reliably bring challenging 6-axis output to the machine. hyperMILL’s Optimizer controls the orientation of the spindle, as the sixth axis, to align the cutting blade to the workpiece while guaranteeing optimal machining within limits for demanding machines with limited rotation axes, such as fork heads.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools