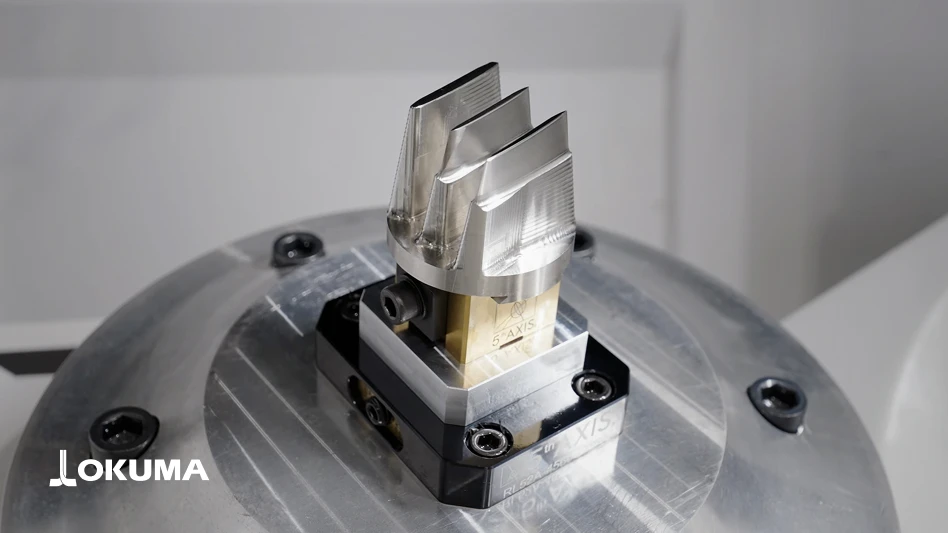

An in-depth approach on developing a 5-axis machining plan, focusing on maximizing machine capacity and achieving the fastest return on investment (ROI) possible.

Jack Rushlander, technical sales manger-East at Jergens Inc., discusses Layout and Planning Techniques for 5-axis Machining Centers.

Walk thru a complete planning process in SolidWorks beginning with raw material and ending with a finished part. Discussions include:

- Machine work envelope considerations

- Raw material and finished part layout

- Machining access considerations

- Maximizing the machine capability

- Planning for automation

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools