Bill Barker, product manager for Rösler/AM Solutions post-processing equipment for North America, discusses post-processing of metal 3D-printed parts.

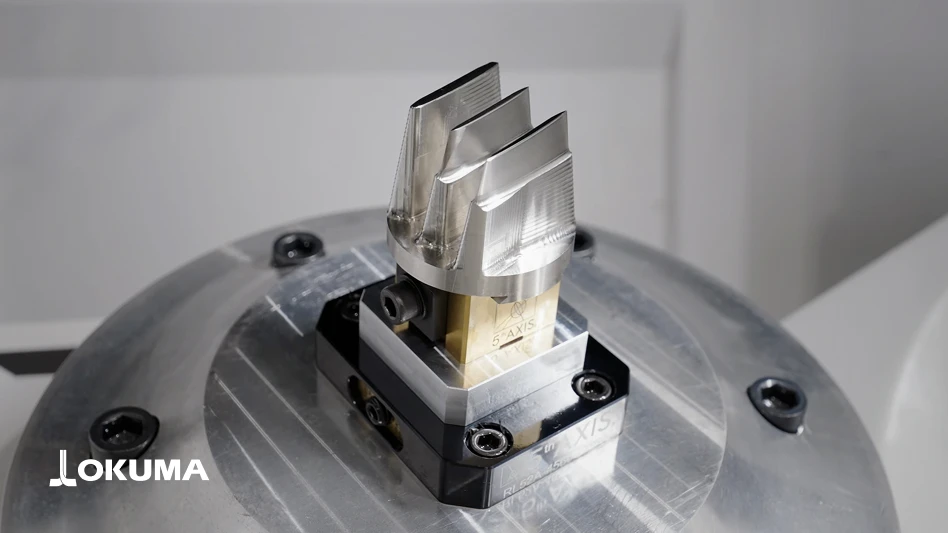

When 3D printing components, much time is invested in selecting a printer and optimizing the part design, and very little time is spent thinking about post-processing the parts once printed. This presentation reviews the steps used to process 3D-printed metal parts in particular, and goes through some useful examples of how designing for post-processing should be a strategic step in your build process.

Rösler Metal Finishing is a global leader in surface finishing for all industries (mass finishing equipment, shot blasting equipment, additive manufacturing equipment, media and compounds). They serve North American customers from their 300,000ft2 manufacturing campus in Battle Creek, Michigan, and support global customers through their worldwide network.

Latest from Aerospace Manufacturing and Design

- Workholding Roundtable to feature expert insights on a booming market

- OnRobot to host Build Your Automation Roadmap event

- 1.25-micron resolution linear optical encoder

- Delta Air Lines orders 31 Airbus widebody aircraft

- AGV virtual path navigation system

- GE Aerospace demonstrates narrowbody hybrid electric engine

- 1, 2, and 3-axis standalone motion control systems

- TMTS 2026 explores AI-powered sustainable manufacturing and more