Gisbert Ledvon, vice president of marketing for HEIDENHAIN Corp. in North America, explains how to improve productivity, reduce quality inspection time, and make 5-axis machining more attractive and safe through digital transformation.

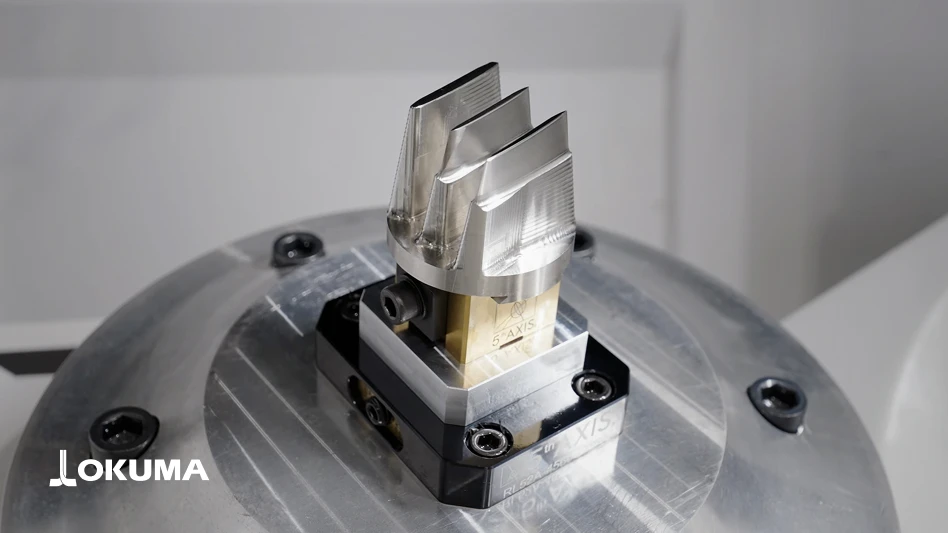

The possibilities for digital transformation in 5-axis machining are numerous. They include 6-D graphically guided model aided setup, graphically programming on the CNC, cutting tool inspection and the digital part, improving in-process inspection time, and minimizing energy consumption per part, consequently reducing environmental impact in manufacturing.

HEIDENHAIN develops and manufactures linear and angle encoders, rotary encoders, digital readouts, length gauges and numerical controls for demanding positioning tasks. HEIDENHAIN products are used primarily in high-precision machine tools as well as in plants for the production and processing of electronic components.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools