The right metalworking fluid does a lot more than you think, and it is an often-overlooked strategic tool for manufacturers.

Chris Porsch, sales director at Blaser Swisslube discusses Metalworking Fluids: The Minor-League Player with a Major-League Impact.

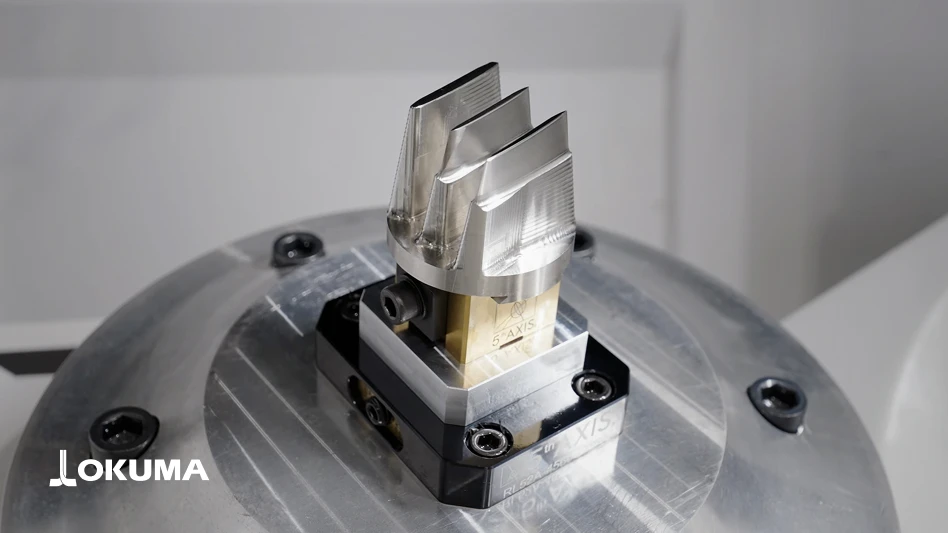

The cost of any metalworking fluid is a small fraction of the total investment into a manufacturing process. At the same time, it has an oversized impact because it touches everything in the shop, from tools to machines, parts, and people. The idea that this minor player – around 0.5% of the production cost – influences the success of the other 99.5% is what we call the “leverage effect” of metalworking fluids. It means that the right metalworking fluid does a lot more than you think, and it is an often-overlooked strategic tool for manufacturers.

In this session you will take away improvement ideas with measurable ROI and learn:

- The impact of the right metalworking fluid on major cost centers in the shop

- How to use coolant to extend tool life, increase cutting speeds and gain process stability

- Examples of improvement goals from other shops, from productivity to health and safety

- How to reduce hours on unpleasant maintenance tasks and protect your valuable CNC machines

Latest from Aerospace Manufacturing and Design

- The Lee Company opens Innovation Center

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family