Covering new CNC motion control and process monitoring technology, focusing on the digital twin with dynamic collision monitoring and machine component monitoring in conjunction with overall process monitoring.

Gisbert Ledvon, director-business development machine tool at HEIDENHAIN discusses Automation and Monitoring as a Subsequent Technology to Optimize Machine Utilization.

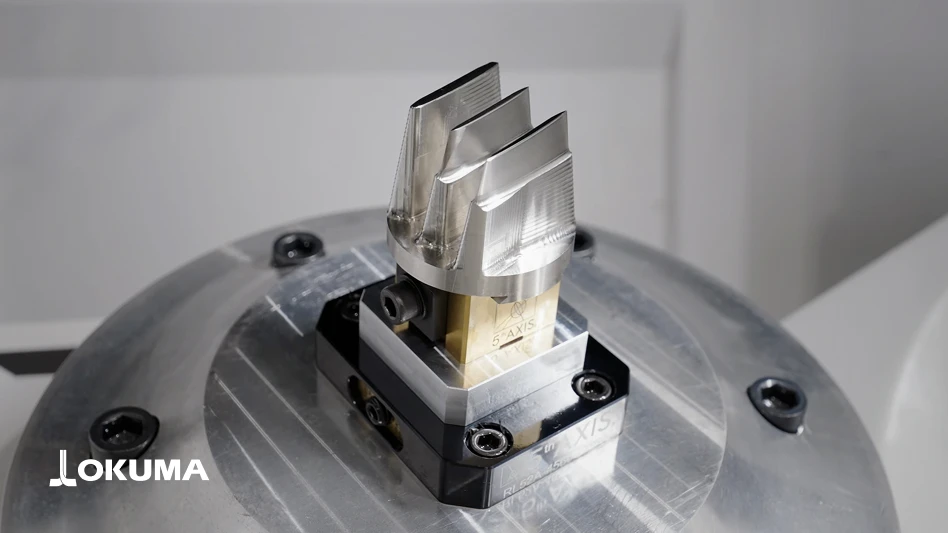

Learn how to make the digital shop floor a reality utilizing the latest CNC motion control technology and the related software and hardware components used in conjunction with modern 5-axis machining centers.

Discussed are the important process steps, broken down into small bite size sections, from program preparation to part setup and in process monitoring. Also covered is an explanation on how the overall process monitoring can help improve process reliability and keep the overall machine usability rate high.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools