One of the most difficult challenges in manufacturing is improving the production efficiency of complex parts requiring multiple machining operations. This is especially true when the parts ultimately used in critical functions are crafted from exotic materials. In developing and implementing strategies for two key parts produced at GE Aerospace in Wilmington, North Carolina, Jonathan Porter, senior manufacturing manager-production process and equipment, and Christopher Marshall, lead manufacturing engineer, partnered with Hainbuch America Corp.’s sales and application staff to implement a program slashing production time while delivering multiple other advantages.

“The parts in question include a Stage 8-10 compressor spool used in our jet engines and a forged shaft that we manufacture for an external customer,” Porter explains. “The parts are machined in a dedicated manufacturing cell on a DMG NT 4300 DCG Mill/Turn center. The spool is machined from a combination of Inconel and Rene alloy, and the shaft is Inconel. Both parts are manually loaded with the aid of lifting equipment. Operations performed include rough and finished turning on both the I.D. and O.D. and milling.”

Defining the system

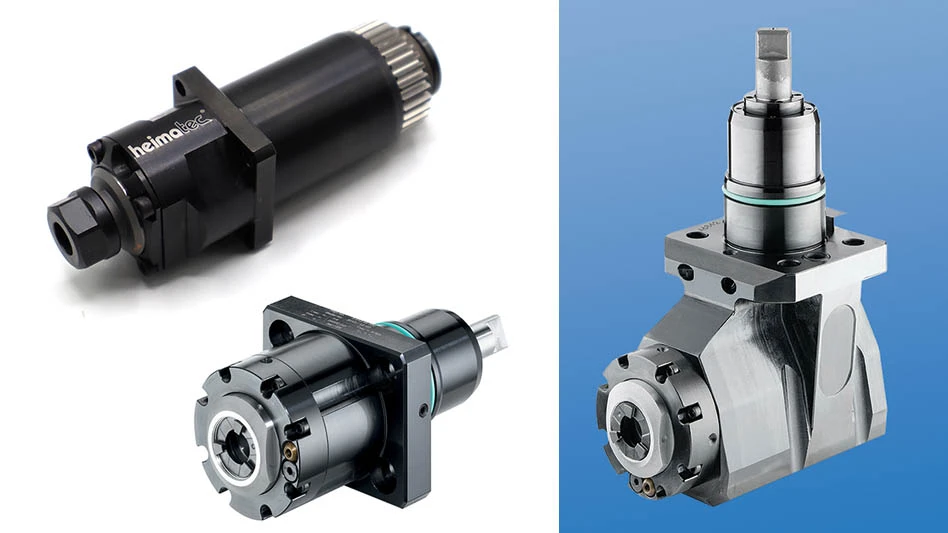

After evaluating the initial production process, the GE team centered on an improved workholding system as the optimum means of achieving their goals. Porter says, “Initially, we considered designing and building a system in-house but, after evaluating several available concepts, we decided the Hainbuch centroteX system was a solution that could meet all our needs.”

Edward Reames, southeast regional sales manager for Hainbuch America Corp., says, “The number of operations required, the complexity of the parts, and the fact I.D. and O.D. operations were involved, posed a real challenge.”

According to Jim McCraw, application engineering manager at Hainbuch America Corp., “Successful partnering begins with developing a thorough understanding of the customer’s manufacturing process, from beginning to end, to properly define the best workholding system. This starts by learning the terminology and methods the customer currently uses and realizing how a single operation or process can be dependent on a prior operation, as well as subsequent machining.

“One of the greatest strengths we bring to the relationship is an extensive experience library of similar applications we’ve successfully developed for other customers facing similar challenges. By developing a constructive dialogue between our Hainbuch staff and the GE Aerospace team, we were able to collaborate and develop a protocol that could improve the process, as well as better utilizing the machine’s capabilities.”

Applying the solution

Reames defines the process: “The system we developed began by outfitting the spindle with a special Hainbuch centroteX 400mm Machine Adaptor. Specialized clamping bushings are essential to efficient operation, as well as maintaining critical tolerances.

“Because of the complexity of the parts, virtually all of the components we supplied were unique to the specific applications. Our Engineering Department designs and produces the specialized fixtures and workholding devices and then retains the production programs and designs so any reorders can be handled in a timely manner.

“For the first operation on the shaft, we developed customized segmented clamping bushings of 212.98mm diameter, as well as a special centroteX T212 Size 8 mandrel and a custom endstop with specified locating length. The second series of operations requires flipping the part 180° and thus enables use of the same mandrel. A clamping bushing of 220.37mm diameter was supplied, as well as an additional custom endstop.”

Marshall states, “Adequate clamping is essential as the forging starts out at 250 lb. The initial measurements are 10.5" I.D. and 13" O.D. Following machining operations, the I.D. is 9.5" and the O.D. 11.5".”

Reames explains, “For the compressor spool, we supplied a special O.D. chuck, for which Hainbuch created a custom designed centroteX flange. For the initial operations, we used a special segmented clamping bushing of 103.99mm diameter, a centroteX T211 size 5 extended mandrel, and a custom endstop with specified locating length. For the secondary machining operations, the same mandrel was used as the part is simply flipped around. The segmented clamping bushing is the same diameter, and a custom endstop is also in place.

“To facilitate clamping, there are small flaps machined onto the I.D. In the second operation, we have to reach deeper into the mandrel to get to those flaps, which is why we had to have an extended mandrel.”

“Of the two parts, the spool was definitely more challenging because it was made up of different segments combined as one assembly that was not very robust for clamping,” McCraw adds. “Although the largest component of the operation involved turning, we incorporated milling where needed to minimize chatter and vibration. Overall, rigid workholding is very important and, with our solid centroteX platform, we were also able to integrate existing fixtures wherever needed.”

“The strategy we devised for both parts was based on accomplishing as much machining as possible in the first setup and then flipping the part to complete the process,” Porter notes. “This eliminates the need for another machine for milling, and thanks to the efficiency of the centroteX design, allows faster setup for operation, as well as high precision that literally exceeds our required tolerances.”

To maximize efficiency, the mill/turn center is equipped with tooling for both parts (12 tools for the shaft and 40 for the compressor). Redundant tooling eliminates the need for excessive load/unload times. A combination of standard and specialized tools is required.

“As machine capabilities, tooling advancements, and complex programming continue to evolve, the workholding rigidity becomes much more crucial,” McCraw says. “Redundancy and modularity are extremely fluid with the centroteX system in that we can immediately respond in the event of others’ tooling or fixture failures, or recurring engineering changes.”

Positive results

Development and implementation of the new system from initial evaluation through design and testing lasted more than a year, but Porter says, “The result was worth it. We reduced run times from 14 hours to 8 hours, and we’re holding a surface finish of 63 microns.”

GE Aerospace’s Marshall sees additional advantages the improved system provides. “We not only eliminated the need for a second machine – a substantial savings in money and time – we found the new setup is much easier for our operators to use. Changeover times are faster, and workholding is secure enough to enable us to go into new processes on the same machine. All told, we’re doing more, and we’re doing it better. It was a significant challenge, but partnering with the Hainbuch group, we’ve been able to exceed expectations all around.”

HAINBUCH America Corp.

https://www. hainbuchamerica.com

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- CAE to deliver full flight simulator to Embraer-CAE Training Services

- Website helps users quickly search, evaluate, specify machine tool accessories

- HondaJet Elite II Emergency Autoland is FAA certified

- Software for creating measurement programs updated

- Nidec Aerospace establishes Atlanta hub to accelerate electric propulsion innovation

- Brochure for high-precision motion control, nanopositioning automation, piezo solutions

- Forecast 2026 Webinar

- America Makes announces two project calls worth $8 million