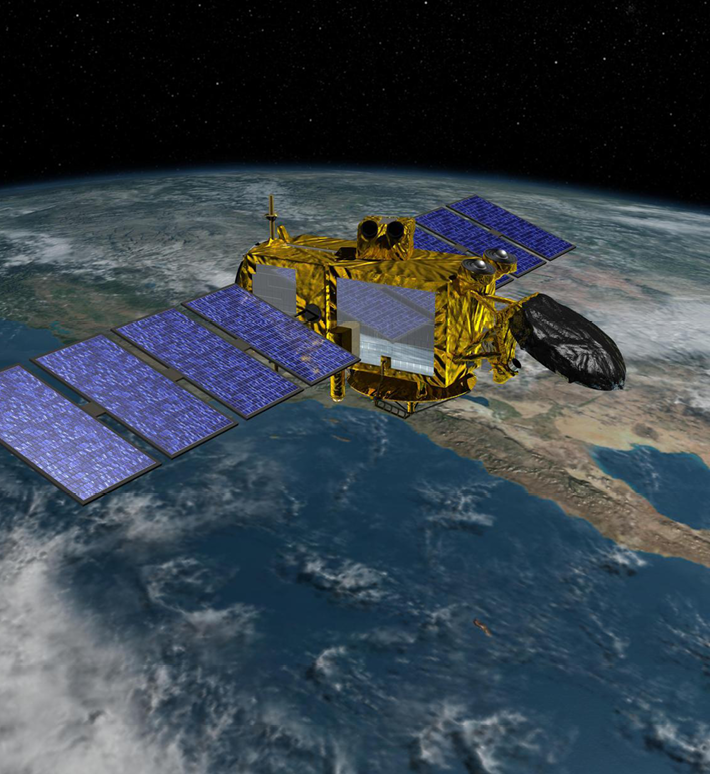

The harsh environment of vacuum and microgravity presents a challenge to components, demanding capabilities not commonly encountered on Earth. This is especially true for motion control systems where movement is their primary function. Motors require considerable power to operate, can generate excessive heat, introduce unwanted vibrations, and create contaminants.

Combating these issues comes at a cost. Higher power requirements need larger power systems generating more heat, requiring larger cooling systems. This can lead to unwanted vibrations, requiring more robust damping systems, and contaminants can cause havoc on instruments and other

To address the challenges:

1. Optimize power consumption

In space applications, power comes at a premium – every watt wasted by a non-optimized system costs precious resources. Optimizing for power consumption includes customizing motor windings to deliver peak dynamic torque at the desired operating speed. This requires proper integration of high-precision components, such as low-inertia, high-efficiency rotors. Depending on the application, engineers tailor each motor to deliver the necessary performance while accounting for power constraints in the system. Using proprietary, proven algorithms, Lin Engineering optimizes torque and speed, noise reduction, heat generation or loss, and power optimization.

2. Manage temperature

Two critical temperature concerns affecting hybrid stepper motors in space are temperature range and the amount of heat generated. Satellites and other spacecraft operate in extreme temperatures, requiring rugged designs for externally mounted systems.

For example, heat affects the strength of magnets embedded in the rotor. As heat increases, motor performance decreases. A solution – permanent magnets. Constructed from rare-earth samarium-cobalt or neodymium alloys, they provide greater magnetic power at higher and lower temperatures.

Heat also impacts the life of bearings used in motors, shortening the lifespan of the whole system. Using bearings with grease that can withstand temperatures from -80°C to 200°C, including dry-lube or

Excessive heat generated by the motor can be a

3. Control vibration

Launching a spacecraft into orbit is violent, as components are exposed to high-amplitude vibration, low-amplitude vibration, and shock from several directions. In addition, stepper motors generate vibrations during normal operations.

Optimizing motor windings minimizes the resonance frequency that develops at specific operating speeds. Using components machined to high concentricity and dimensional accuracy helps ensure rotors or shafts do not introduce unwanted vibrations into the system.

In space, vibrations must be avoided because they can affect

4. Limit outgassing, contaminants

On the microscopic level, gases and liquids are trapped inside of paints, coatings, greases, and materials. In the vacuum of space, these trapped gases inside the motor can expand or condense, and liquids evaporate, introducing unwanted contaminants into the environment. If these contaminants settle on imaging sensors or measurement instruments, they can reduce overall performance or render them useless.

Motors can be designed to minimize outgassing, when all stepper motor components – end caps, stator, rotor, screws – are manufactured from low-outgassing materials. Most components on the motors are metal alloys, which, without paint, are rated for vacuum use. Plastic materials should be non-outgassing polyamide or nylon. Sealed bearings filled with low-outgassing lubricants are also available. All components are thoroughly cleaned and vacuum baked, then each stepper motor is assembled in a

Ensuring the longevity of components that go into space is a factor of the time and effort put into

Lin Engineering Inc.

http://www.linengineering.com

Explore the October 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Aura Aero selects Florida manufacturing, assembly site

- EMUGE-FRANKEN's high performance end mills

- IMTS 2024 Booth Tour: Engis Corporation

- How can we make electric vehicles more user-friendly?

- Leaders in Manufacturing webinar will ease your fears about changes in the industry

- October Lunch + Learn with EMUGE-FRANKEN USA and Okuma America

- October Lunch + Learn with SMW Autoblok

- marcus evans announces the Aerospace & Defense Manufacturing and R&D Summit 2024