Royal Machine & Tool Corporation has announced the forming of a special in-house Aerospace Service Group.

New equipment and software have been purchased, and a new building addition is planned to meet the increased fixturing needs of the Aerospace Industry.

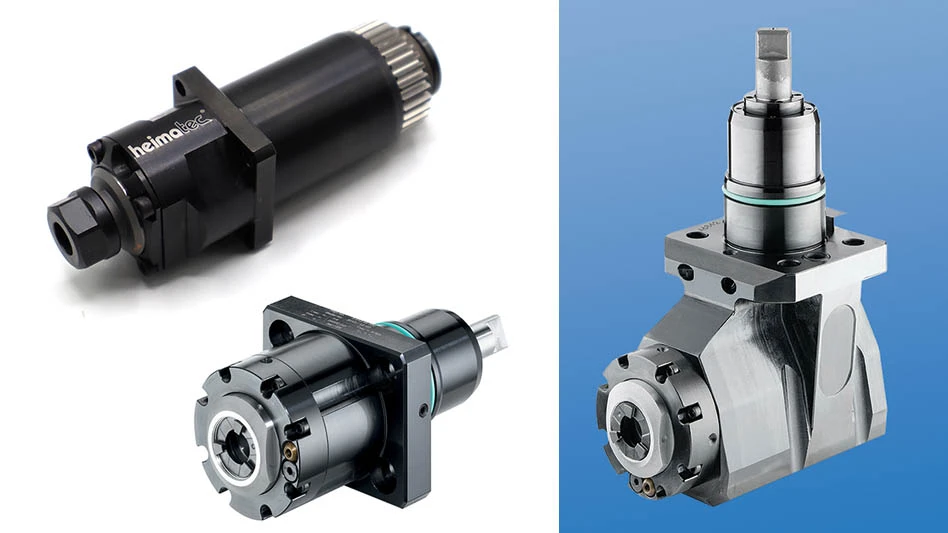

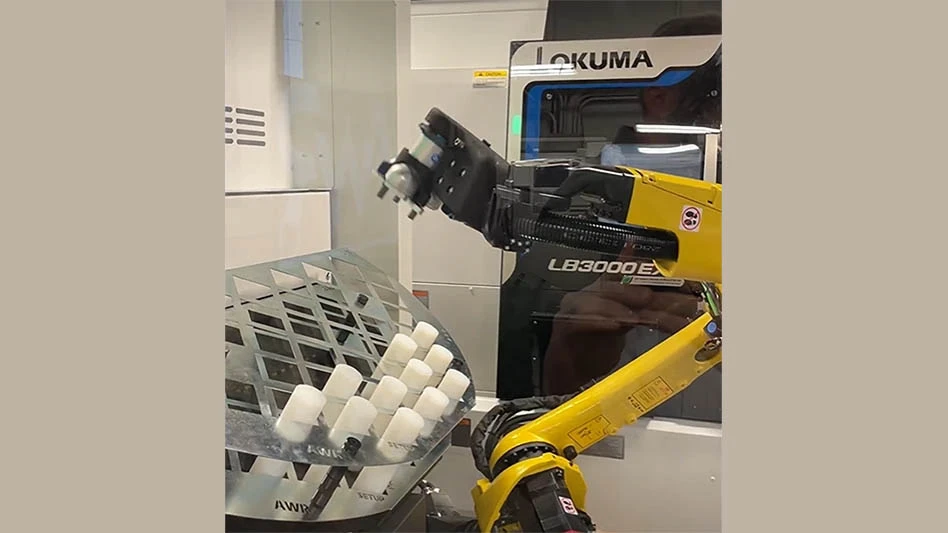

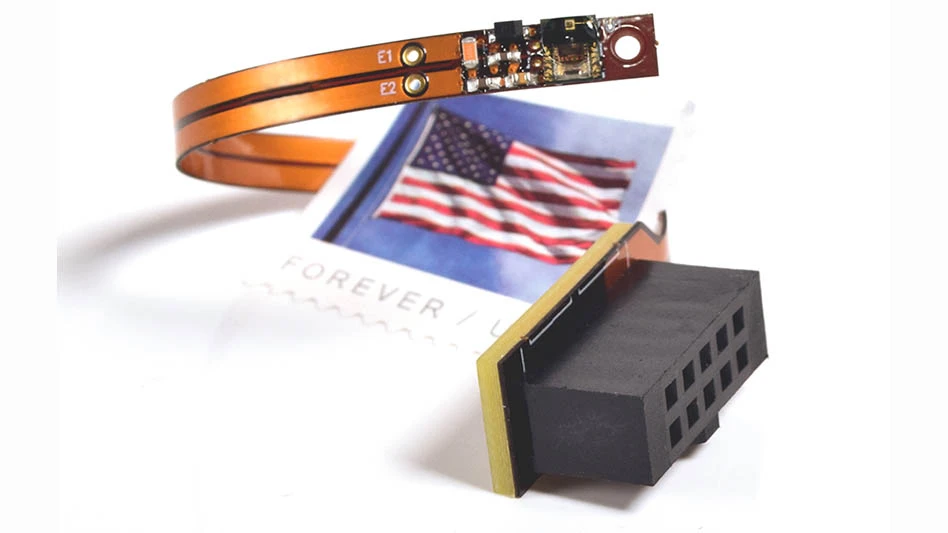

Recently, Royal has invested in five new pieces of equipment for their turning and milling departments to expand their capabilities in capacity and machining. The engineering department has upgraded to Solid Works Software, which enables solid modeling in their designs and is most vital in optimizing the fixture at the design phase by the offering of 3-dimensional viewing.

During the coming year, a 1,200ft2 building addition is planned to provide manufacturing space to consolidate operations and to improve work flow.

Explore the May 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- HondaJet Elite II Emergency Autoland is FAA certified

- Software for creating measurement programs updated

- Nidec Aerospace establishes Atlanta hub to accelerate electric propulsion innovation

- Brochure for high-precision motion control, nanopositioning automation, piezo solutions

- Forecast 2026 Webinar

- America Makes announces two project calls worth $8 million

- Jaw force gauges

- Air India orders 30 Boeing 737 MAX jets