Offering speed, compact size, dual spindles, and simultaneous multi-tool cutting capability, the Muratec MW35 performs secondary operations for screw machine blanks and fasteners. The combined, simultaneous operations of X1- and X2-axes and a built-in, high-speed, swing-type loader, offer a fast-overall part-to-part cycle time. The machine’s low height allows for clear shop floor visibility.

Equipped with a built-in workpiece ejector, the MW35’s spindle has a maximum speed of 6,000rpm for faster acceleration and deceleration control. A servo-controlled, high-speed, swing-type loader contributes to a faster overall part-to-part cycle time.

The MW35 comes with a gang-type tool plate and an optional sub-tool rest for a forming tool (X2-axis).

Murata Machinery USA Inc.

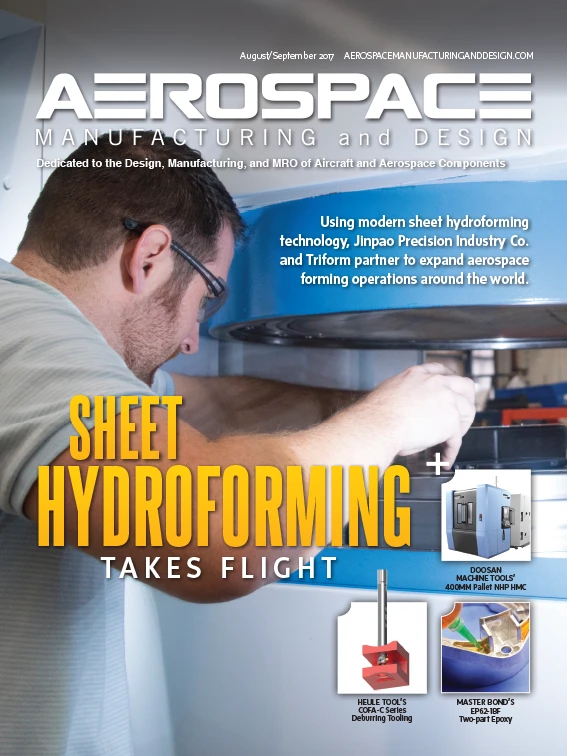

Explore the August September 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators