Thread milling grade with elevated temperature resistance

The Tiger∙tec Gold WSM37G thread milling grade features a physical vapor deposition (PVD) aluminum oxide (Al2O3) coating for an elevated level of temperature resistance and long tool life.

A titanium aluminum nitride (TiAlN) base coating on the carbide substrate offers a high level of wear resistance, and the multi-layer coating is topped with a polished gold-colored zirconium nitride (ZrN) layer for friction resistance and wear detection. The smooth rake face minimizes friction, while chip breakers specifically developed for thread milling and a defined corner radii produce threads in accordance with standards.

The indexable inserts have a positive basic shape geometry with three cutting edges and are available in D67 universal geometry for maximum tool life or D61 geometry with anti-vibration land for a high level of operational smoothness when using large projection lengths or under difficult conditions.

The inserts are for milling threads with a nominal diameter from 16mm or UNC 3/4. The indexable inserts can be used universally to thread mill steel, stainless steel, cast iron, non-ferrous metals, heat-resistant super alloys, and steel hardened up to 55HRC (ISO P, M, K, N, S, and H).

Walter USA LLC

https://www.walter-tools.com

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Making workholding work for you

- CAE to deliver full flight simulator to Embraer-CAE Training Services

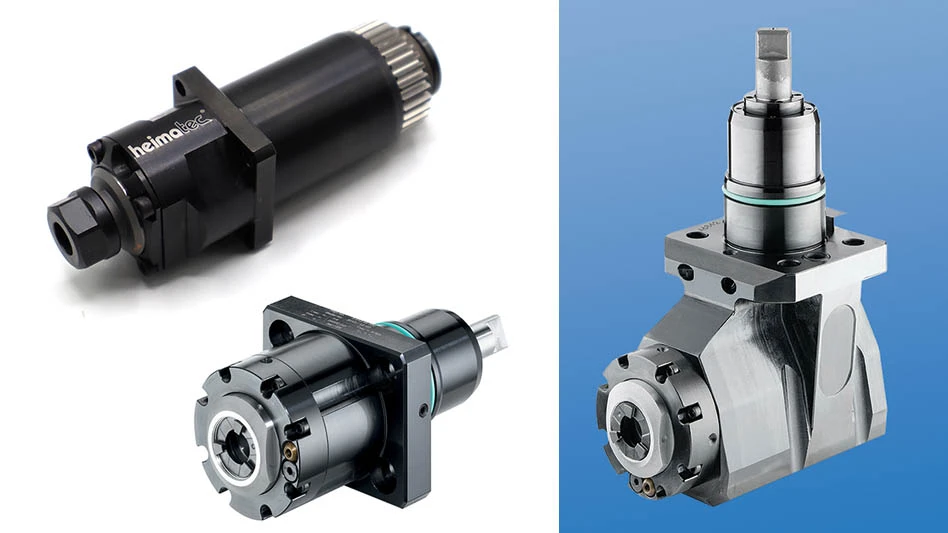

- Website helps users quickly search, evaluate, specify machine tool accessories

- HondaJet Elite II Emergency Autoland is FAA certified

- Software for creating measurement programs updated

- Nidec Aerospace establishes Atlanta hub to accelerate electric propulsion innovation

- Brochure for high-precision motion control, nanopositioning automation, piezo solutions

- Forecast 2026 Webinar