What is the traditional image that springs to mind when you think of turning operations on a lathe? In most cases, it is a cutting insert mounted in a conventional toolholder, addressing a bar of material, being flooded with coolant from one or more coolant delivery pipes.

Turning has been done this way for years, but what if there was a smarter way of delivering coolant directly and precisely to the tool/workpiece interface? This would have several benefits. Not only would it allow minimum quantities of fluid to be used, while still providing effective cooling, it would also make the chip sufficiently brittle to fracture more easily, permitting increased cutting speeds and extended tool life (thanks to reduced work hardening and notch wear). Not to mention the benefit that eliminating downtime and component damage associated with long, tangled chips, and the subsequent facilitation of problem-free, lights-out machining would bring.

Seco Tools, as part of a shared patent with Rolls-Royce, has developed a dynamic system capable of delivering all of these advantages known as Jetstream tooling, originally introduced in late 2008.

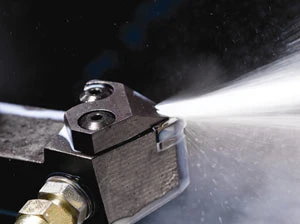

The design offers strategically placed coolant exit holes machined into a patented swiveling top clamp (known as the inducer) on the insert holder. When coolant is pumped through these small diameter apertures, it produces an acute, high velocity jet stream that penetrates the precise friction zone between the cutting edge and the workpiece, providing superior lubrication, cooling and chip removal.

The rapidly cooled chips become brittle and easy to lift away from the rake face, in short and easily managed pieces, eliminating chip evacuation issues and negating the problems of component damage caused by tangled chips.

Although originally developed to help the aerospace industry to machine titanium, the benefits of Jetstream tooling are equally significant on most aerospace alloys, aluminum alloys, stainless steels and alloyed steels.

By producing a high velocity jetstream and delivering it to the precise friction zone between the cutting edge and workpiece, Jetstream tooling quickly achieves ROI.

Jetstream Tooling is typically delivered at pressures of 200psi to 1,015psi, and at an optimized angle of trajectory that provides maximum productivity benefits. It is an off-the-shelf standard product based on a traditional toolholder design that covers both ISO inserts and Seco's multidirectional turning and grooving system.

Standard Jetstream tooling systems will fit 70% to 80% of CNC turning machines including Mazak, Mori Seiki, Nakamura- Tome, DoosanDaewoo, Okuma and Gildemeister models.

Substantial Savings Titanium is one beneficiary of Jetstream tooling technology. This aerospace material is a notoriously poor conductor of heat, which means high temperatures remain at the point of cut, leading to alloying tendencies that can produce welding, galling and smearing – cutting edges can very quickly be destroyed. Titanium's cutting characteristics produce a thin, high velocity chip that is difficult to break into manageable chips.

Often the chips will displace conventional coolant delivery systems leading to coolant starvation at the cutting point and component damage.

Using a conventional tool with a high positive rake and sharp edges can minimize these effects, but the long chips created are difficult to control. In Seco tests, such a tool running at a cutting speed of 130sfpm, a feedrate of 0.010ipr, and 0.080" depth of cut produces a five minute cycle time on a Ti-6AL4V component. Using Jetstream tooling, it was possible to increase cutting speed to 260sfpm and reduce cycle time to three minutes, representing a 40% improvement.

Seco says that even greater benefits, such as enhanced surface finish, can be gained by pairing Jetstream tooling with the company's Duratomic-coated MF5 chipbreaker insert, which is designed to generate very low cutting forces. The surface of the insert is interrupted by two distinct deflectors to assist chipbreaking, and three strategically positioned slots that allow a free flow of Jetstream-delivered coolant.

Seco Tools

Troy, MI

http://www.secotools.com/wps/portal/northamerica/Epi_1204

Explore the August September 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators