Dramatic technological change is coming to the business of aircraft maintenance, repair and overhaul (MRO). At Vitesse Aviation Services in Dallas, TX, customers are beginning to require that their parts be overhauled using digital data. Whenever available, the part's original CAD file is to be used in its overhaul. If not available, the CAD data is to be created by reverse engineering.

This is nothing short of an upheaval at Vitesse-Dallas, and eventually throughout MRO. The all-digital technologies of CAD and reverse engineering – integrated with CAM and CNC machining – are replacing manual methods that MRO shops have relied on for decades. For CAM, Vitesse chose Edgecam from Planit Solutions and for CAD it chose solid modeler Inventor from Autodesk Inc.

Edgecam was chosen for its tight integration with Inventor. Inventor had been previously chosen because most Vitesse customers used it. There will always be some manual machining in MRO, but at Vitesse, Edgecam's speed, flexibility and power makes it ideal for the digital future.

Both Edgecam and Inventor are sold and supported by ECAD Inc. They are part of a $200,000 Vitesse-Dallas investment in digital technology. That sum included Vitesse-Dallas's first piece of CNC equipment – a V-50 vertical milling machine from Leadwell CNC Machines Manufacturing Corp. – and a reverseengineering system built around a portable coordinate measuring machine (CMM).

Driving this investment is the fact that aircraft designed with CAD and CAM are beginning to show up in MRO operations. This means that even some older airliners and business jets arrive at the hangar with CAD data for their components.

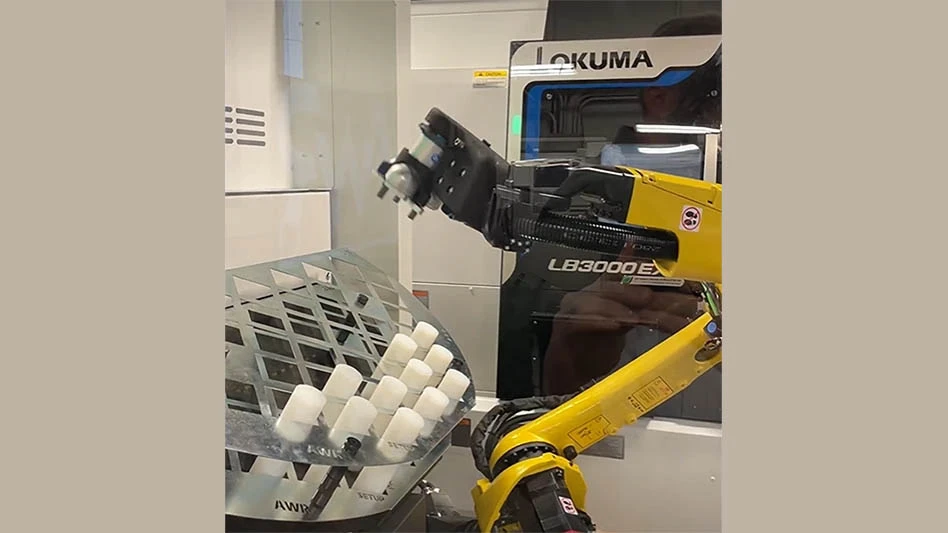

Making aircraft overhaul parts on Vitesse Aviation's new Leadwell machining center is Machinist Art Saldivar. Image courtesy of Vitesse Aviation.

Aircraft owners "are getting more sophisticated about how they do business," says Steven R. Hall, Vitesse director of repair and overhaul. "Even though the parts have not really changed, they are much more particular about how we handle them."

CAD and CAM are to be used whether the job is machining a replacement for a complicated structural component, or simply redrilling a hole in an existing part, and inserting a new bushing.

"Our customers now want repairs handled on an alldigital basis," Hall explains. "They want the replacement parts standardized. They want the process standardized. They want all the details tracked on a computer. They do not want to rely on any manual measurements and they don't want anyone interpreting drawings."

Manual methods and finely-honed skills have been the core competence of MRO since the dawn of manned flight. When replacements were unavailable or on extended lead times, machinists repaired and rebuilt parts, often beneath a wing of a grounded aircraft.

Traditional MROs used everything from precision-engineered height gages to ordinary measuring tapes to get dimensions, and then transfer them by hand to paper. MROs had little choice. Aircraft builders were reluctant to hand over their drawings if parts were still in production, and many older drawings were lost or damaged.

Of the drawings that did survive, dimensions were sometimes incomplete and/or easily misinterpreted, late-stage design changes often were not shown, and in-service modifications were not consistently tracked.

This forced MRO technicians to reverseengineer parts. They spent hours and sometimes days verifying every dimension before cutting any metal. Machining was done on manually operated mills and drills. Machining skills were paramount, and always will be. This also meant that a great deal of the "aircraft on ground" (AOG) business has always been based on the simplest of work instructions: "fabricate per sample," meaning., make a replacement part that is the dimensional and functional equivalent of the original.

Even the earliest digital results at Vitesse-Dallas dramatically shortened delivery times, which is always critical for them. The core of its business is AOG emergency service – on-the-spot, right-now repairs and replacements – meaning that an aircraft worth $10 million to $50 million is going nowhere fast.

Vitesse focuses on landing gear, flight-control hydraulics, and some structural parts. However, for all but the last two of its 40 years, this MRO shop was the corporate flight-services department of Texas Industries Inc., which sold the business to Vitesse Inc. in mid-2006. The highly successful move into a much larger commercial MRO market followed.

Vitesse has FAA certifications from airlines and from builders of airliners and corporate jets. Many of these OEMs now share digital parts data with Vitesse.

Investing Carefully

For Vitesse-Dallas, AOG is a rapid-response business with complete, end-to-end service and fast turnaround. Parts for overhaul are disassembled, evaluated, reverse-engineered, manufactured, tested, finished, tested again and reinstalled. Vitesse maintains extensive capability at Love Field in Dallas, for:

- Non-destructive testing and non-destructive inspection (NDT/NDI), including magnetic particle, fluorescent dye penetrant and eddy current.

- Heat-treating for stainless steel and aluminum alloy parts, and stress-relieving for high-strength steel parts.

- Plating (chrome, nickel and cadmium), aluminum anodizing, cleaning and painting.

"We have always done great work keeping aircraft in service," Hall says. "We can often do all this in a week, even if we have to work all night."

Management at Vitesse-Dallas views the move to digital data as a strong tail wind, and had no difficulty justifying the decision. There was little doubt that was the best way to satisfy demanding customers – and provide a new competitive edge.

So, why Inventor and Edgecam? The reseller, ECAD Inc., had previously sold Inventor and Edgecam to the in-house MRO operations of Southwest Airlines, also based at Love Field. In addition, Account Manager Benjamin Gibson was willing to train people on Edgecam before purchase. This meant a huge cut in perceived risk, yet very few software vendors are willing to train users before they buy.

Further reassurance comes from Edgecam Solid Machinist. Solid Machinist seamlessly moves part geometry to and from Inventor – from solid modeler to machine tool. That eliminates any chance of error in missing an engineering change or small feature, gets around potential hiccups of data translation, and ensures that handling geometric and dimensional data is bulletproof.

The Edgecam users also quickly saw that CAM and CNC reduce or even eliminate process variability. That dovetails nicely with the efforts of the airlines and OEMs of airliners and business jets to reduce potential kinks in their supply chains. Variability was wrung out of aircraft manufacturing in the 1990s, if not sooner.

The Leadwell machining center, Vitesse Aviation's first CNC machine tool.

Satisfying Customers

Results are piling up. On the first Vitesse CNC job – airliner floor support/seat rails – production time was cut by more than half. Manually machining each one took 45 hours – a full week on a Bridgeport mill. On the Leadwell, the first one was done in about 20 hours. The time continued to fall as the work progressed. Now jobs that formerly took up to eight days can be done in as few as two.

These parts are skinny, twisty T-shaped aluminum extrusions with 1" x 2" cross-sections. Despite their length – up to 12ft long – designing and building a machining fixture made little sense as job runs were too short. Expert machinists handled each part's relocations and reorientations quickly, greatly aided by Edgecam, Hall explains.

After just a few months. Vitesse landed an order for 20 floor support/seat rails with a promise of more to come. Even with the inevitable learning curves, Mayberry did it in just three weeks.

CAM and CNC mean a big change in thinking about production methods. "With CNC, all the hard work is done once you start making chips. With manual machines it is just the opposite," Mayberry says.

Winning More Business

"The real question for us when TXI sold the business to the Vitesse corporation was how well we could use new digital technologies to achieve solid payback and then make money on a consistent basis," Hall says.

Two years later, he is cheerfully confident, noting that Vitesse has gained distinct new advantages over each group of competitors.

- In-house MROs of aircraft manufacturers and airlines have higher overall costs, while costs at Vitesse are dropping.

- Machine shops may offer lower parts prices, but cannot match the end-to-end services Vitesse provides, or its speed, soon to be enhanced with reverse engineering.

- Most independent MRO shops have yet to grasp the benefits of going digital, giving Vitesse a first-mover advantage.

As aircraft OEMs provide more parts data and repair specifications in digital and solid-model formats, this plays directly to Vitesse-Dallas' new capabilities. Whether the geometry is from the original CAD file or is reverse-engineered, all of it goes through Edgecam.

As for the bottom line, Vitesse is on track to meet projections for a highly conservative 20%, three-year return-on-investment (ROI) as Vitesse continues to bring in jobs. The ROI calculation covers the entire $200,000 and was measured on an operating-profit basis.

Business Transformation

For the foreseeable future, most of Vitesse-Dallas's business will be overhauling parts that still have no CAD data. This part of the MRO business is about fast response – getting aircraft off the ground and back in service – rather than about cost.

"The real issue for our customers is the number of calendar days that elapse before their aircraft goes back into service," Hall points out. Nevertheless, he continues to look at the aero parts business for fill-in work so the new machine tools run more hours per month – if costs are covered.

To bring the Vitesse full-service business model into the digital world, Hall is readying a move into reverse engineering, as noted. Soon to go into use are a portable CMM with digital dimensioning capability and software to integrate touch-probe data with solid modeling, prototyping and machining.

Vitesse machinists will soon have accurate and complete digital data for every part they repair or make from scratch. With Edgecam, Vitesse will also be able to process this data into solid models, inspection documents, technical publications for aircraft maintenance, reports for owners and the FAA.

When the world changes, it's not enough to change with it. "What's really required is finding ways to get out in front of the change with the best technology," Hall sums up. "We expect to create a big new customer-service opportunity to get a lot more business. We do not intend to wait for it to come to us. We expect CAD and CAM to keep us on the leading edge of change."

Explore the September October 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Forecast 2026 Webinar

- America Makes announces two project calls worth $8 million

- Jaw force gauges

- Air India orders 30 Boeing 737 MAX jets

- Speed increasers for lathes, Swiss-style machines

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- A look at the latest in the defense industry

- Workholding Roundtable to feature expert insights on a booming market