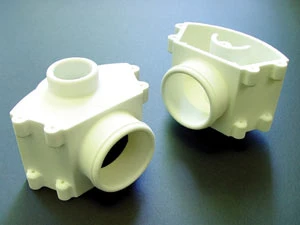

Paramount PDS is using EOS' PA 2210 FR material for rapid manufacturing of commercial aircraft components. PA 2210 FR, the first flame retardant polyamide for lasersintering, has passed independent testing for aircraft burn, smoke and toxicity, as well as UL 94 V-0 flammability.

Prior to flying PA 2210 FR parts, Paramount's commercial aircraft customer performed its own testing to confirm flame retardancy properties. "An independent lab tested PA 2210 FR under FAR 25.853 specifications, and others. It passed. In fact, the material outperformed five materials that were tested at the same time," says Jim Williams, president of Paramount PDS. Meeting all regulations, Paramount proceeded with rapid manufacturing of more than a dozen flight hardware components for a commercial luxury aircraft.

Williams said, "Laser-sintering with PA 2210 FR has enabled this aircraft company to slash production lead times and eliminated tooling costs. Our customer has qualified and adopted laser-sintering for production of custom polymer flight hardware." Williams also notes that the company has leveraged the freedom of design that rapid manufacturing offers. "Each of the aircraft components was specifically designed and engineered for rapid manufacturing. This resulted in complex configurations, which could not be molded or machined, that addressed the form and functional needs of the aircraft hardware application," states Williams.

According to Jim Fendrick, vice president of EOS of North America, Paramount PDS is the first in the U.S. to offer PA 2210 FR laser-sintered components. Fendrick said, "Paramount had customers that needed flame retardant materials. When it learned of the new material, the company became a beta test site. Throughout the past eight months, Paramount has reported that it is very pleased with PA 2210 FR's processing and properties."

Williams explains, "From the very first run, we have been building great parts. There have been no problems, whatsoever. In fact, there is no difference between processing parts with PA 2210 FR and making them with EOS's other polyamides." Williams also notes no changes to visual or dimensional part quality. We tested it in our own in-house metrology lab and confirmed that there is only negligible loss in material strength compared to unfilled polyamide," says Williams.

Explore the December 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools