Denver – Expliseat SAS, Paris, France, is the recipient of the International Titanium Association’s 2014 Titanium Application Development award. Gilles Duval, the vice president of procurement for Expliseat will be accepting the award on behalf of the organization. Nominated by Vincent Tejedor, the company’s chief technical officer, Duval and Expliseat were recognized by the ITA for the development and commercial launch of a commercial aerospace interior cabin product simply known as the “Titanium Seat.”

Duval expressed his appreciation for receiving the ITA award, saying it reflects Expliseat’s “four years of hard work” to develop the Titanium Seat. “This is amazing. Our team is very proud and over-motivated for the next challenges.”

The Titanium Seat received European Aviation Safety Agency (EASA) certification approval on April 1, 2014, certifying it meets European Union safety standards, for both the Airbus A320 and Boeing 737 jetliners. The U.S. Federal Aviation Agency (FAA) also certified the seat, which is designed for single-aisle aircraft for short and medium hauls. It is the lightest commercial aircraft seat ever certified, according to Duval.

Expliseat’s first contract was to supply 220 seats to Air Méditerranée, a French airline, for an Airbus A321 aircraft. The delivery and installation took place earlier this year, Duval said. “We managed to deliver the seats without any delay and customer is very satisfied. We are a new company and we need to show that we are reliable and that we do what we say.” He said negotiations with another airline, to use the seat in a Boeing 737, are in the final stages of discussion.

Duval explained that the Titanium Seat weighs 4kg (9 lb) per passenger, while the best competitor is twice that weight and the standard seats installed in most commercial aircraft are around 13kg (29 lb) per passenger. Duval touted the cumulative, long-term weight-saving advantages of the seat, saying it offers an annual fuel savings of up to $500,000 per aircraft.

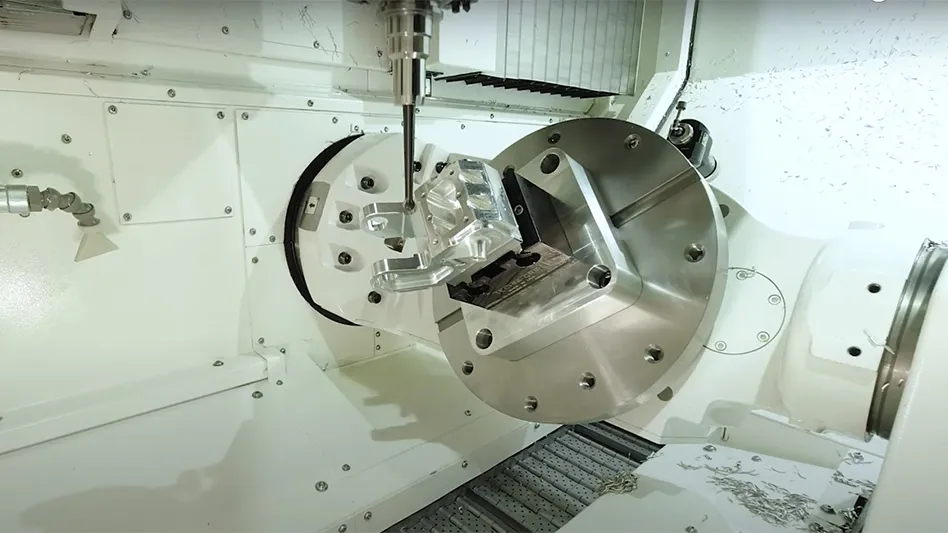

The Titanium Seat is manufactured through a combination of a near net-shape process and machining. There are 10 patents on the Titanium Seat program, all internationally filed. Duval declined to spell out details of the production technology, and said only that the carbon fiber composite and titanium are both “premium, aerospace grade materials.” Expliseat subcontracts production of the Titanium Seat with major industrial companies. The seats are assembled at a facility in Toulouse, France.

Benjamin Saada, chief executive officer, Jean-Charles Samuelian, executive director, and Tejedor formed Expliseat in 2011. The initial goal for the privately held company was to bring together innovation, ergonomic design and industrial efficiency in a single product: the Titanium Seat.

Source: ITA

Latest from Aerospace Manufacturing and Design

- Still time to register for the May 16 Manufacturing Lunch + Learn

- NIAR to add electric aircraft test capability

- Arnold Magnetic Technologies' custom electromagnetic capabilities

- Garmin earns best supplier recognition from Embraer for 9th consecutive year

- Dillon Manufacturing's Carbinite coating

- #43 Manufacturing Matters - 2024 Spring Aerospace Industry Outlook with Richard Aboulafia

- US operator UrbanLink orders 20 Lilium Jets

- TJ Davies’ retention knobs