The Garant HB 7010-1 turning grade is for high wear resistance in lightly interrupted cutting and difficult operating conditions.

Garant HB 7010-1 has a hard, wear-resistant, thermo-resistant aluminum oxide AI2O3 and titanium carbonitride Ti(C,N)CVD coating, which protects the carbide substrate at high cutting speeds and process temperatures. The carbide substrate is resistant to plastic deformation, splintering, and brittle fracturing, offering a longer tool life with continuous cutting at high speeds.

Straightened crystal structures in the coating resist ablation while its smooth surface enables optimum chip evacuation, reducing friction between the component and the tool material, which also lowers process temperatures.

The core of the indexable insert is ductile. The carbide substrate is graded having an increased proportion of titanium nitride (TiN) in the outer layer to adapt the thermal expansion coefficient to the coating. The coating adheres to the substrate and the coating cannot shear away, even at high process temperatures.

Hoffman Group USA

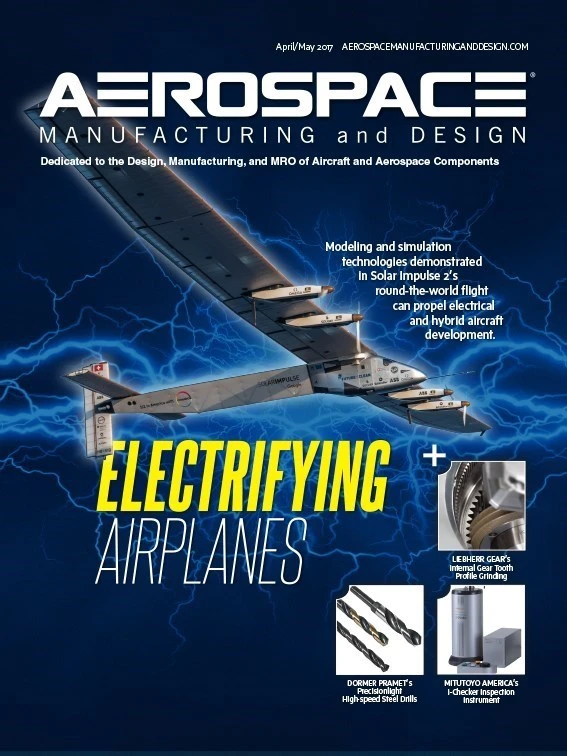

Explore the April May 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators