Nanocomp Technologies (NCTI) has developed a different approach to carbon nanotubes.

While nanotubes have been around for quite some time, the traditional forms are powder-like, which do not possess the fundamental performance, or the necessary conductive and structural properties, and they are extremely difficult to successfully incorporate into existing manufacturing processes. NCTI has solved this problem by creating very long carbon nanotubes and fabricating them into physically strong, lightweight, electro-thermally conductive fibers, yarns and sheets.

"The impact on the aerospace industry is quite profound," says Peter Antoinette, president and CEO of NCTI. "[The nanotubes] have high strength, high conductivity – both electrical and thermal – and the ability to shield from EMI (electromagnetic interference) and EMP (electromagnetic pulses)." These properties allow for lightweight electrical cables, lightweight shielding for wires, lightweight shielding for avionics from EMI and EMP, and eventually lightweight composites that would be able to augment traditional carbon fiber.

Copper wire is prevalent throughout airplanes. These wires are relatively heavy; they fatigue, and are prone to vibration and corrosion. The newest planes coming into service in the 21st century are pushing for lighter weight and lower fuel consumption.

One of the options to reduce the weight of the cable systems is to create lightweight shielding for cables from carbon nanotube materials.

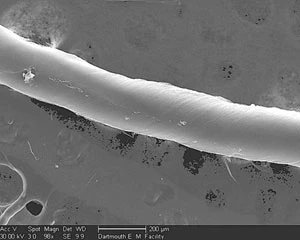

Example of NCTI's physically strong, lightweight, electro-thermally conductive carbon nanotube sheet

NCTI is experimenting with replacing the braided copper shielding currently being used. "In doing so, it looks like you can save up to 40% of the weight of a co-ax cable, and 30% of the weight of a shielded twisted pair," Antoinette notes. "On a 787, with 61 miles of cable, that could result in a savings in excess of 2,000 lb. And a C-17 has 121 miles of cable, so obviously you're looking at 4,000 lb of potential savings." Leaving the copper conductor in place and replacing the shield alone will yield such weight savings, he explains.

Another benefit of the nanotubes' electrical conductivity is the ability to create large area sheets that can be seamed together to cover an entire aircraft, replacing the bronze phosphor copper meshes that are on aircraft with a carbon nanotube (CNT) composite material. The CNT composite material allows people to examine lightening strike protection at a far lighter weight, and with a better match to current carbon fiber fuselages.

"Right now, people are taking metal screens and laying them over these new graphite composite fuselages, and that creates all sorts of problems," Antoinette says.

"You have mismatches with thermal expansion, and they are quite heavy, so they soak up a ton of resin. The CNT composite materials fit right into today's resin system used to lay up the carbon fibers. It actually becomes part of that resin system. You are not carrying along a heavy weight material that is parasitic; you have weight that is actually useful in the structure." Thermal conductivity is another benefit of CNTs. The aircraft business has become fly-by-wire, with mechanical linkages virtually gone. Heat must be removed from the high-power electronics, and more effectively managing heat is important for adding more power into aerospace electronics.

"We have high strength and we have other properties, but there's no reason to replace something that's worked for 100 years [such as copper] unless you have something profound, and I think what's profound is having equal-to or better performance while also decreasing the weight of what is up there," Antoinette says.

NCTI is currently in deep evaluations with major aerospace manufacturers to insert CNT composite materials into manufacturing processes. The company is also working under a number of SBIR contracts with the Federal government to confirm applied properties of conductivity, structural integrity, and shielding from radar and lightening.

"We are involved right now in several programs that are doing qualification for insertion into programs, with the timeline likely to be middle to end 2010," Antoinette says. "So we are not in production yet, but we are moving out of the research phase and into the qualification phase." In addition to the multi-functional benefits of NCTI's materials, the company delivers real-world benefits that outpace traditional solutions, among them lower weight, high-frequency conductivity, flame resistance and higher breaking strength.

The U.S. Government has, and continues to invest in the company's research, based on consistent results to date and the potential of more innovation in the future.

Nanocomp Technologies Inc.

Concord, NH

nanocomptech.com

Explore the August September 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators