GIE Media’s Manufacturing Group

About the presentation

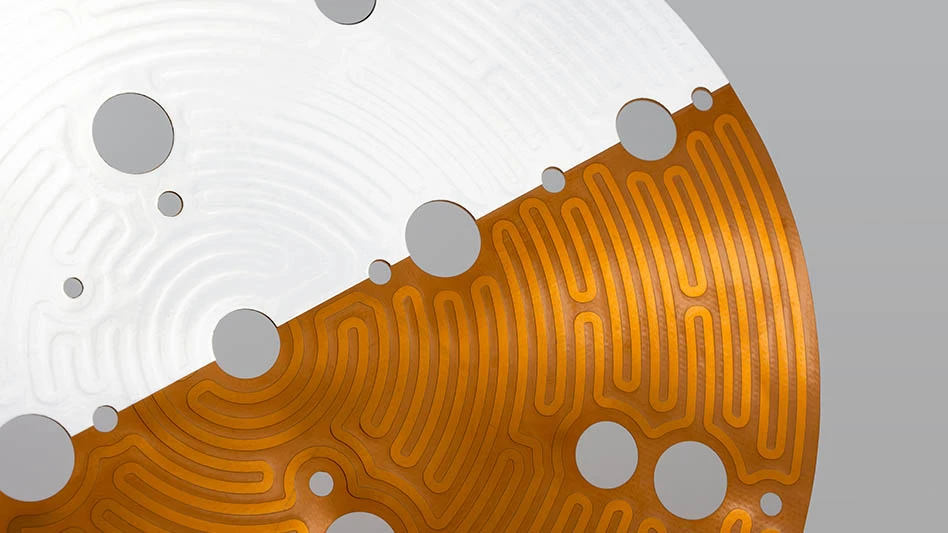

Stamping lines generate scrap when production conditions slide outside the “process window” the line is tuned to run within: ranges of tonnage, material, gauge, lubrication, blank positioning, etc. In reality, these parameters are not all sufficiently controllable. When this happens, even the most sophisticated in-line data acquisition and process control/AI technologies are incapable of bringing production outcomes into quality compliance without compromising part quality or piece cost. AI and control algorithms simply cannot override basic laws of mechanics and material behavior. Smart Engineering is a systematic approach to engineering a process that not only has narrow quality metrics but also a wide process window. This presentation provides insight into the digital execution of this approach, starting from early product design, through process development, all the way to validation/certification of its true potential in producing quality compliant stampings.

Registration

Powered by AMT and managed by GIE Media, The IMTS 2022 Conference features 69 different sessions you won’t want to miss so register today. Focused on a range of topics that include process innovation, plant operations, quality/inspection, and automation, The IMTS 2022 Conference addresses improving productivity; improving part quality; and developing a stable, competent workforce to lower the cost of manufacturing in the United States and create new levels of market demand.

Meet your presenter

Kidambi Kannan is a technical specialist with AutoForm Engineering USA. His responsibilities include the role of technical specialist and training management. Following a Ph.D. in Materials Science and Engineering from the University of Maryland, College Park, Kidambi joined EASi Engineering as a project engineer. He eventually served as project manager for sheet metal forming projects. Kidambi joined AutoForm Engineering USA Inc. in 2002 as technical manager and has been intimately involved in the rapid and industry-wide expansion of AutoForm’s presence throughout the past 19+ years.

About the company

AutoForm was founded in 1995 in Zurich, Switzerland. Since then, AutoForm has grown continuously and rapidly, and the company is now recognized as the leading provider of software solutions for sheet metal forming and assembly simulation.

Today, over 3,500 users in more than 1,000 companies in 50 countries around the world, trust in and rely on AutoForm for their key engineering and manufacturing operations.

Leading the way in research and development, AutoForm's innovations for rapid and reliable validation of design, engineering, and manufacturing processes on sheet metal stampings have profoundly revolutionized the market.

Producing tremendous improvements in quality, time, and cost, AutoForm is an acknowledged industry standard at virtually every automotive OEM and at leading suppliers of tooling, stampings, and materials worldwide.

We are proud to have earned genuine customer loyalty because of both our products and our people. Our mission is to provide innovative technological sheet metal stamping software solutions along with best-in-class support, which give our customers competitive advantages worldwide.

We would be happy to help your company optimize their stamping capabilities. Contact us to see how you can get a free trial of AutoForm's stamping software products.

AutoForm Engineering USA Inc.

www.autoform.com

Offices: Troy, MI & Grand Rapids, MI USA

Phone: 888.428.8636 ext. 3

Email: sales@autoform.com

Latest from Aerospace Manufacturing and Design

- OMA and NIMS partner to launch semiconductor technician credentials

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Blaser Swisslube, NIDEC Machine Tool America partner

- Extrusion crosshead combines concentricity adjustment, fastener-free assembly

- Vertical Aerospace unveils Valo eVTOL aircraft

- 3xD pilot step drill

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.